(1.厦门大学能源学院,福建 厦门 361102; 2.珠海市生产力促进中心,广东 珠海 519000)

(1.College of Energy,Xiamen University,Xiamen 361102,China; 2.Zhuhai Productivity Promotion Center,Zhuhai 519000,China)

DOI: 10.6043/j.issn.0438-0479.201905021

备注

在超临界CO2布雷顿循环系统设计中,为提高系统能量转换效率,需要准确预测风摩损耗.风摩损耗与转子转速、转子几何结构、工质状态密切相关.该文针对2 MPa CO2工质中,高转速(23 kr/min)转子的风摩损耗特性进行数值计算分析.研究结果表明:转子-定子壁面粗糙度对超临界CO2布雷顿循环系统中高转速以及可能出现的较高压强工况下的风摩损耗具有显著影响.已有风摩损耗经验关系式未考虑壁面粗糙度的影响,直接使用可能带来较大误差.风摩损耗随壁面粗糙度和转子转速的增加而增加,气腔宽度的变化对风摩损耗不会造成明显影响.

In order to improve the energy conversion efficiency of the supercritical CO2 Brayton cycle system,it is necessary to accurately predict the windage loss during the system design.Windage loss is closely related to rotor rotation speed,rotor geometry and the state of the working fluid.In this paper,the numerical calculation analysis of high-speed(23 kr/min)rotor windage loss characteristics in 2 MPa CO2 working fluid is carried out.The results show that rotor-stator wall roughness has a significant effect on the windage loss of the supercritical CO2 Brayton cycle under high rotation speed and high pressure conditions.The existing empirical relation of windage loss does not consider the influence of wall roughness,the direct use of which may cause considerable errors.The windage loss increases with both the wall roughness and rotor rotation speed.The cavity width between the rotor and stator does not have obvious influence on the windage loss.

引言

在超临界CO2布雷顿循环系统中,压缩机、汽轮机等涡轮机械是系统中的关键部件.由于循环系统中采用的CO2工质会泄露到涡轮机械的转子-定子腔体内,所以工质将与转子表面发生摩擦作用,造成一定的摩擦损耗,这一损耗被称为风摩损耗.风摩损耗会影响涡轮系统的效率,甚至会对循环系统的安全运行造成威胁.

早期研究人员[1-11]主要通过理论分析和实验手段对风摩损耗开展研究,得到了针对不同工质、工况和转子-定子几何结构的风摩损耗计算关系式.近年来,随着计算流体力学(CFD)技术的发展,国内有很多研究人员[12-19]针对不同尺寸的涡轮机械系统的风摩损耗问题进行了数值模拟研究,得到了转子-定子间气腔内的流场分布情况,并与已提出的风摩损耗计算关系式进行对比,证实了数值模拟方法对于这类问题的适用性.

已有研究主要针对常压下的工质,利用实验结果拟合得到风摩损耗计算关系式,用于预测特定条件下的风摩损耗.不过,这些关系式一般仅能预测常压下、Couette雷诺数(Reδ)小于1×105工况下的风摩损耗,对于预测范围外的工况适用性较差.对于超临界CO2系统中高转速以及可能出现的2~7.4 MPa下的工况,已有的风摩损耗计算关系式是否依然适用,还需要进行更深入的研究.本研究基于数值模拟方法,考虑转子-定子壁面粗糙度、气腔宽度和转子转速等影响因素,对在30 ℃、2 MPa的CO2工质中运行的圆柱形转子的风摩损耗特性进行分析,研究结果可为超临界CO2布雷顿循环系统的涡轮机械设计提供计算和参考依据.

1 数值模拟计算模型

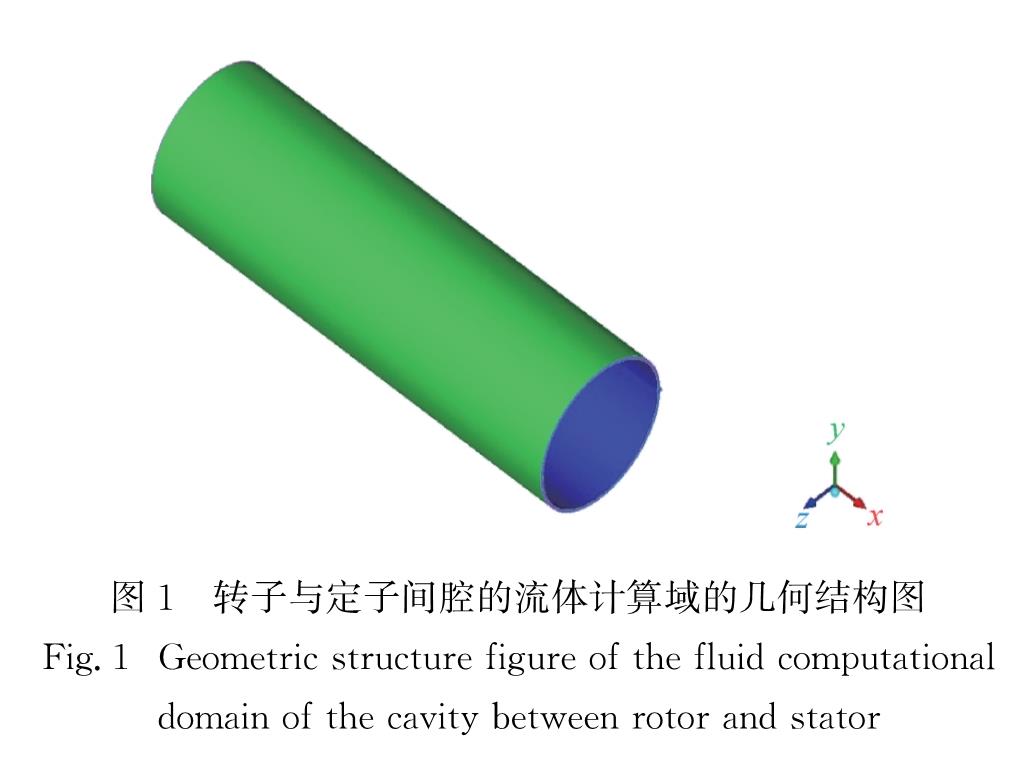

1.1 物理模型涡轮机械转子的风摩损耗发生在转子-定子腔体内.本研究针对这一区域进行几何建模,将转子外壁和定子内壁简化为同轴圆柱面,区域端面简化为环面,得到的抽象流体计算域如图1所示.图中外侧圆柱面为定子内壁面,内侧圆柱面为转子外壁面,两侧环面为风摩损耗区域端面.

图1 转子与定子间腔的流体计算域的几何结构图

Fig.1 Geometric structure figure of the fluid computational domain of the cavity between rotor and stator本研究假定在超临界CO2循环系统内,泄露进入转子-定子间流体腔内的工质状态处于30 ℃、2 MPa下,且腔体内工质不存在轴向流动.采取不同的腔体几何结构,选取转子-定子壁面粗糙度(0~12.5 μm)、气腔宽度(1~4 mm)和转子转速(4.6~27.6 kr/min)作为影响因素,研究其对风摩损耗情况的影响.气腔长度为525 mm,转子外直径为155 mm,气腔宽度由转子外半径与定子内半径决定.

1.2 数值计算方法对于2 MPa的CO2工质,在旋转工况下会产生非常剧烈的湍流运动.一般的湍流模型(如Spalart-Allmaras、k-和k-ω模型)采用Boussinesq各向同性涡黏性假设,但实际上,即使是最简单的边界层内湍流运动的湍流特征依然是各向异性的,因此其在强旋转、大曲率、外受力场作用较强的流场中无法得到与实验结果一致的模拟计算结果.

雷诺应力模型摒弃了湍流黏度概念,直接建立雷诺应力的输运方程,并对其中脉动关联项加以模块化后进行求解,对于强旋转下的流动现象可以取得更准确、更细致的流场模拟结果.本研究模拟中所用网格的y+值大于30,因此在模拟计算中选用标准壁面函数.引入壁面粗糙度进行模拟时,在计算软件界面中输入壁面粗糙度,计算模型对壁面粗糙度无量纲化,将其作为参数引入到壁面函数中,以对近壁面处的流场分布进行模拟.计算中将气腔两端圆环侧面和外侧圆柱面设置为绝热静止壁面,以模拟涡轮机械定子; 将内侧圆柱面设置为以一定转速旋转的绝热壁面,以模拟涡轮机械转子.

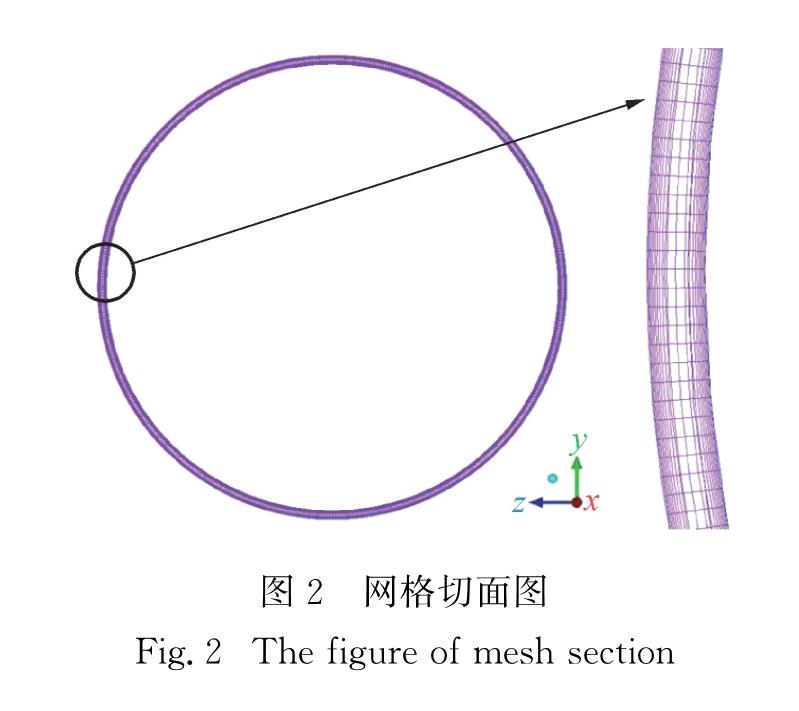

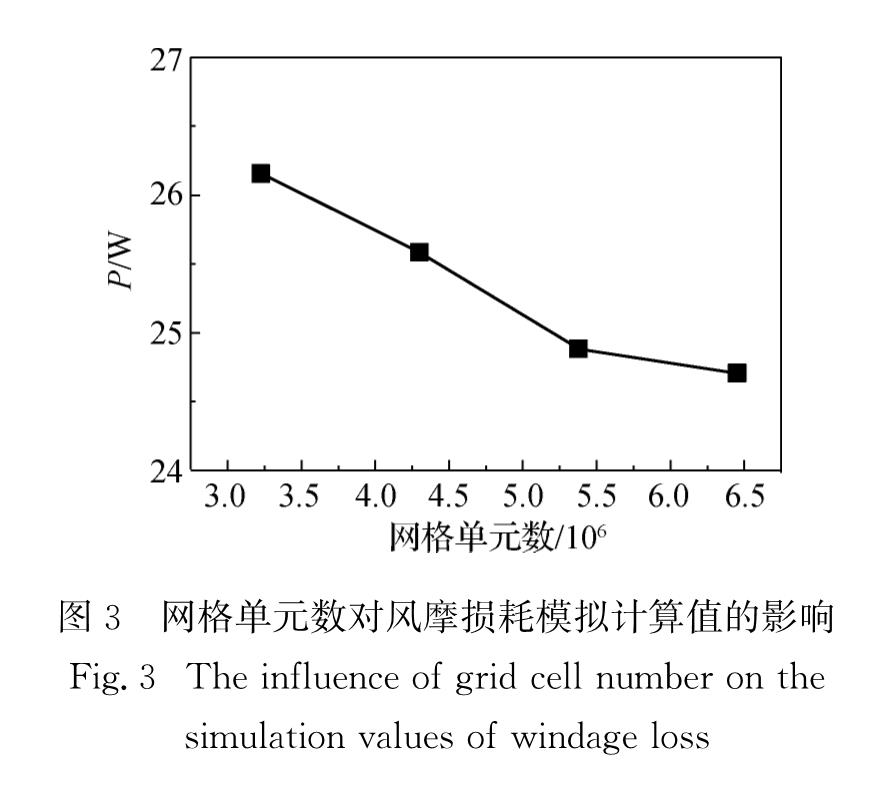

1.3 网格划分为提高网格质量和计算精度,对流体计算域进行结构化网格划分处理.由于在转子和定子附近的流动状况复杂,需要对近壁面网格进行加密处理,径向的网格切面如图2所示.为保证计算的准确性,对网格进行无关性分析.分析过程中,以风摩损耗模拟计算值作为判定依据,以径向网格层数作为影响因素,层数设置为12,16,20和24,对应的网格单元数为3.23×106,4.30×106,5.38×106和6.45×106.以转子-定子壁面光滑工况作为参考工况,风摩损耗功率P的模拟计算值如图3所示.由图可知,模拟计算值随着网格单元数的增加逐渐减小,当网格单元数大于5.38×106 时,P的模拟计算值偏差小于1%.因此认为径向网格层数为20,网格单元数为5.38×106时可满足网格无关性分析要求.

2 模型验证

雷诺应力模型的风摩损耗功率P通常由下式得到:

P=Cfρπω3r4l,

其中,Cf为风摩损耗系数,ρ为工质密度,ω为转子转速,r为转子外半径,l为气腔长度.需要求解风摩损耗系数Cf以确定风摩损耗功率.

在Bilgen和Boulos[9]研究中,假设气腔内没有轴向流动,工质物性不随温度或压强发生变化,以水或甘油-水溶液为工质,采用不同转子-定子结构进行实验,其获得的数据结合文献[1-5]中的实验数据分析得出:

{Cf=0.515(δ/r)0.3Reδ-0.50,当500<Reδ≤1×104,

Cf=0.032 5(δ/r)0.3Reδ-0.20,当Reδ>1×104.

其中,Reδ=ρ ωrδ/μ,δ为转子-定子间的气腔宽度,μ为工质黏度.故对于特定工况,确定工质的黏度和密度、气腔的长度和宽度、转子的转速和外半径即可求得风摩损耗功率.

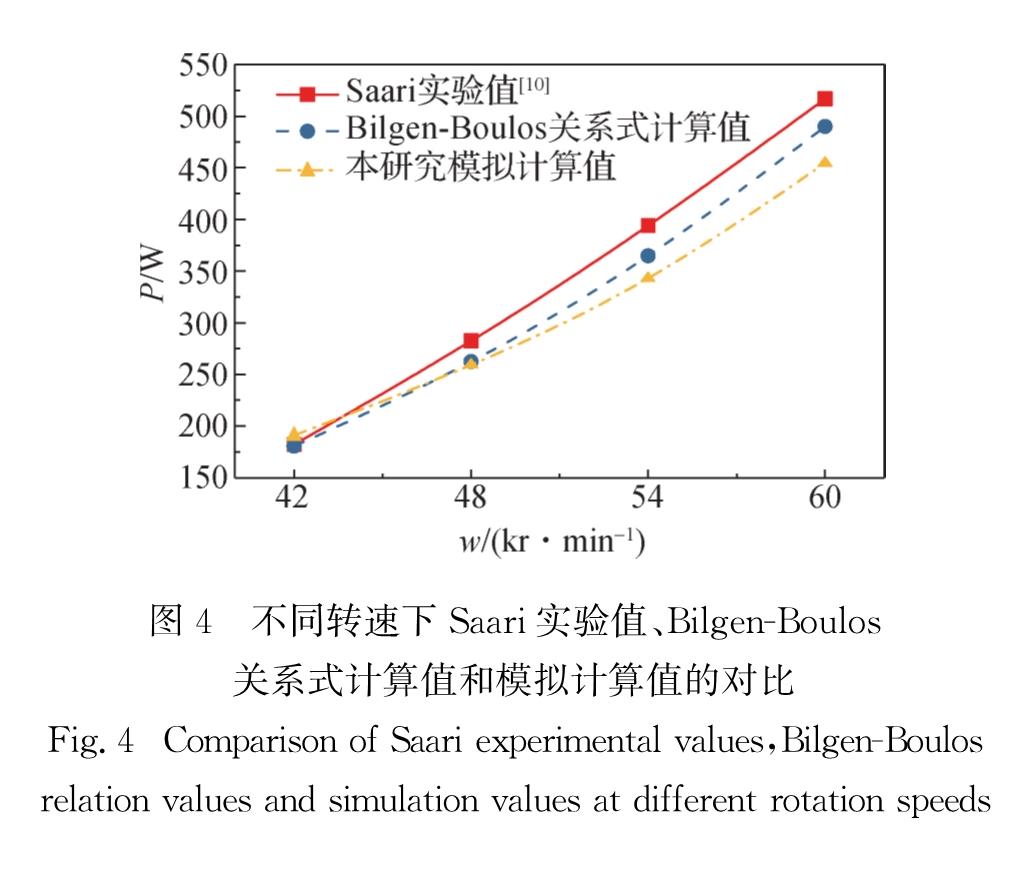

为了验证模拟计算对于风摩损耗问题的适用性,本研究采用Saari的实验数据[10]进行验证.实验中,工质为常压下的空气,密度1.093 kg/m3,黏度19.6 μPa·s; 转子转速为30~66 kr/min,气腔长度为200 mm,转子外直径为71 mm,定子内直径为75 mm,气腔宽度为2 mm; 气腔两端密封,气腔内不存在轴向流动.本研究针对Sarri实验中的工质流动区域进行几何建模及空间离散化,对近壁面网格进行加密处理,设置径向网格层数为15,网格单元数为7.08×105.在模拟计算中,将转子转速设置为42,48,54和60 kr/min,与Saari实验中采取的工况相对应.使用雷诺应力模型和标准壁面函数进行模拟计算,当连续性方程残差小于10-5时判定为收敛.计算完成后,将模拟计算结果与Saari得出的实验数据[10]以及由Bilgen-Boulos关系式[9]算得的计算结果进行比较.如图4所示,本研究模拟计算值与实验值以及Bilgen-Boulos关系式计算值的相对误差小于±15%,证明了该数值模拟计算模型的可靠性.

3 结果分析

3.1 基本流动特征以转子-定子壁面光滑工况作为参考工况描述基本流动特征,该工况下气腔宽度为3 mm,定子内直径为161 mm,转子-定子壁面粗糙度设置为0,转子转速为23 kr/min.使用CFD后处理软件对模拟结果进行处理,得到气腔内工质的压强分布情况和速度分布特征.

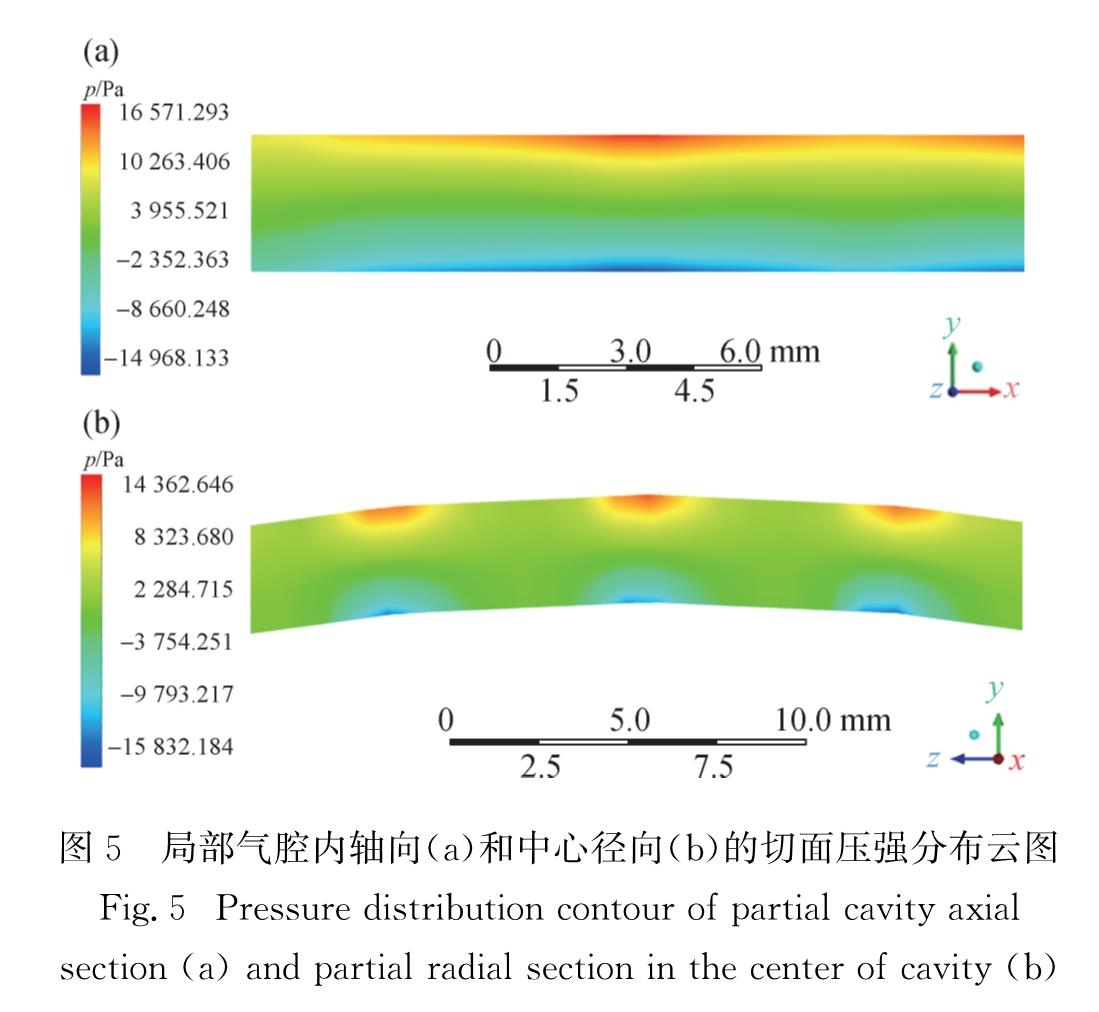

图5(a)和(b)分别为局部气腔内轴向和中心径向的切面压强分布云图.可以看出,负压分布于转子附近,正压分布于定子附近,气腔内的压强不是均匀分层分布,最大正压与最大负压在气腔内周期性成对分布在定子表面和转子表面,气腔中心区域的压力变化幅度小,这说明气腔内存在一定强度的二次流动现象.

图5 局部气腔内轴向(a)和中心径向(b)的切面压强分布云图

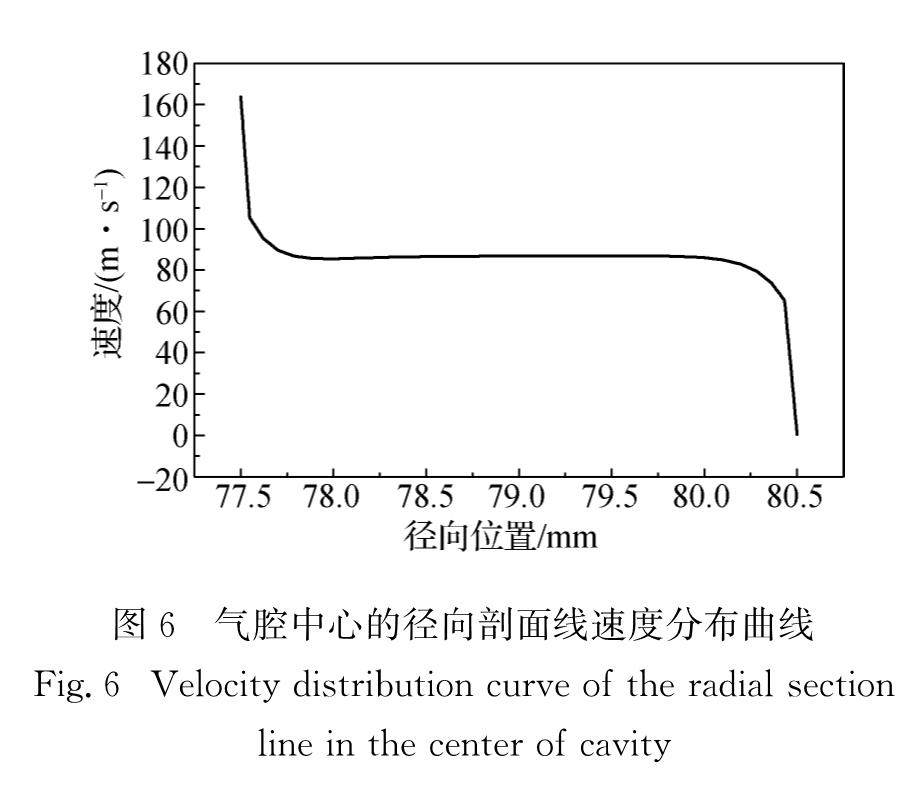

Fig.5 Pressure distribution contour of partial cavity axial section(a)and partial radial section in the center of cavity(b)图6为气腔中心的径向剖面线速度分布曲线图,可以看出,在气腔内位于转子附近的工质,在转子的带动下,以和转子线速度相同的速度流动.边界层内的速度变化剧烈,速度沿径向方向向外剧烈降低至转子线速度的一半左右; 在气腔中心区域,速度保持基本不变直至定子附近; 在定子附近,速度再次剧烈变化,降至0.

图6 气腔中心的径向剖面线速度分布曲线

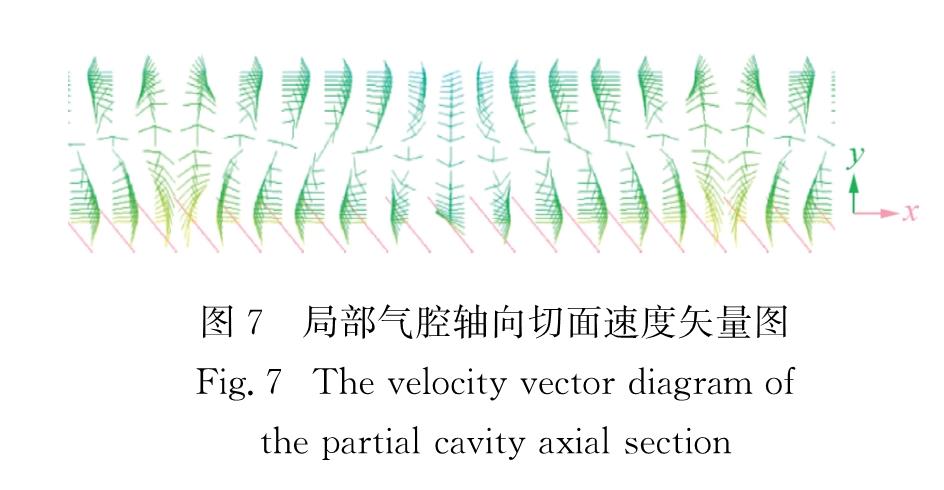

Fig.6 Velocity distribution curve of the radial section line in the center of cavity图7为局部气腔轴向切面速度矢量图,可以看出,气腔中存在着明显的二次流动现象,这种现象被称为泰勒涡,相邻泰勒涡流动方向相反,位置与气腔内最大正压与最大负压相对区域重合.在其他工况下,气腔内的压强分布和速度分布与转子-定子壁面光滑工况下的相似.

3.2 壁面粗糙度对风摩损耗的影响由于材料表面都存在着一定的壁面粗糙度,所以将转子-定子壁面设置一定的粗糙度,以常压与中压下的CO2为工质,设置转子转速为23 kr/min,研究壁面粗糙度对风摩损耗的影响.

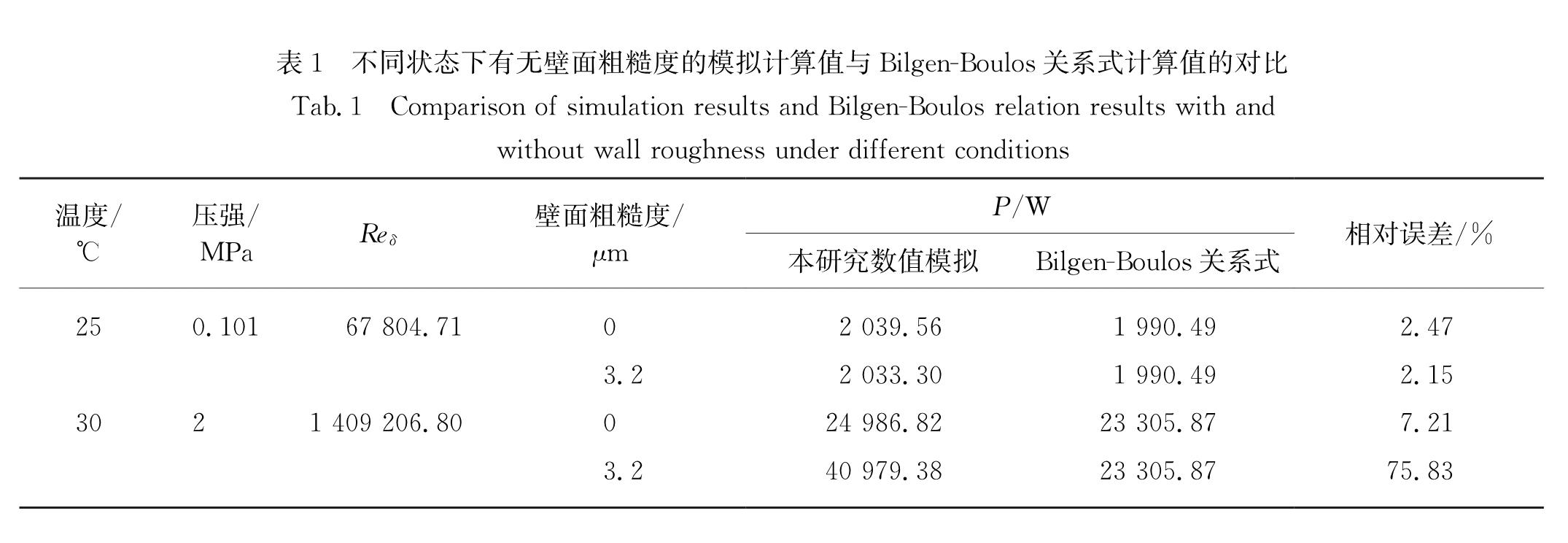

从表1可以看出:常压(0.101 MPa)下,壁面粗糙度分别为0和3.2 μm时,P的模拟计算值相差不大,其与Bilgen-Boulos关系式计算值的相对误差分别为2.47% 和2.15%,说明常压下3.2 μm的壁面粗糙度对风摩损耗几乎不会产生影响.而在2 MPa下,壁面粗糙度为3.2 μm时P的模拟计算值明显高于粗糙度为0的模拟计算值,二者与Bilgen-Boulos关系式计算值的相对误差分别为7.21%和75.83%,说明在2 MPa 的工况下,3.2 μm的壁面粗糙度对风摩损耗有不可忽略的影响.

表1 不同状态下有无壁面粗糙度的模拟计算值与Bilgen-Boulos关系式计算值的对比

Tab.1 Comparison of simulation results and Bilgen-Boulos relation results with and without wall roughness under different conditions结合Reδ分析表明:常压下工质流动的Reδ远小于1×106,湍流程度小,3.2 μm的壁面粗糙度处于黏性底层内,不会对风摩损耗造成影响; 在2 MPa下CO2工质的密度大于常压条件下,在转子转速和几何结构相同的条件下,Reδ远高于常压工况,工质流动的湍流程度很大,3.2 μm的壁面粗糙度处于黏性底层外,对风摩损耗产生了极大的影响,超出了Bilgen-Boulos关系式的适用范围.

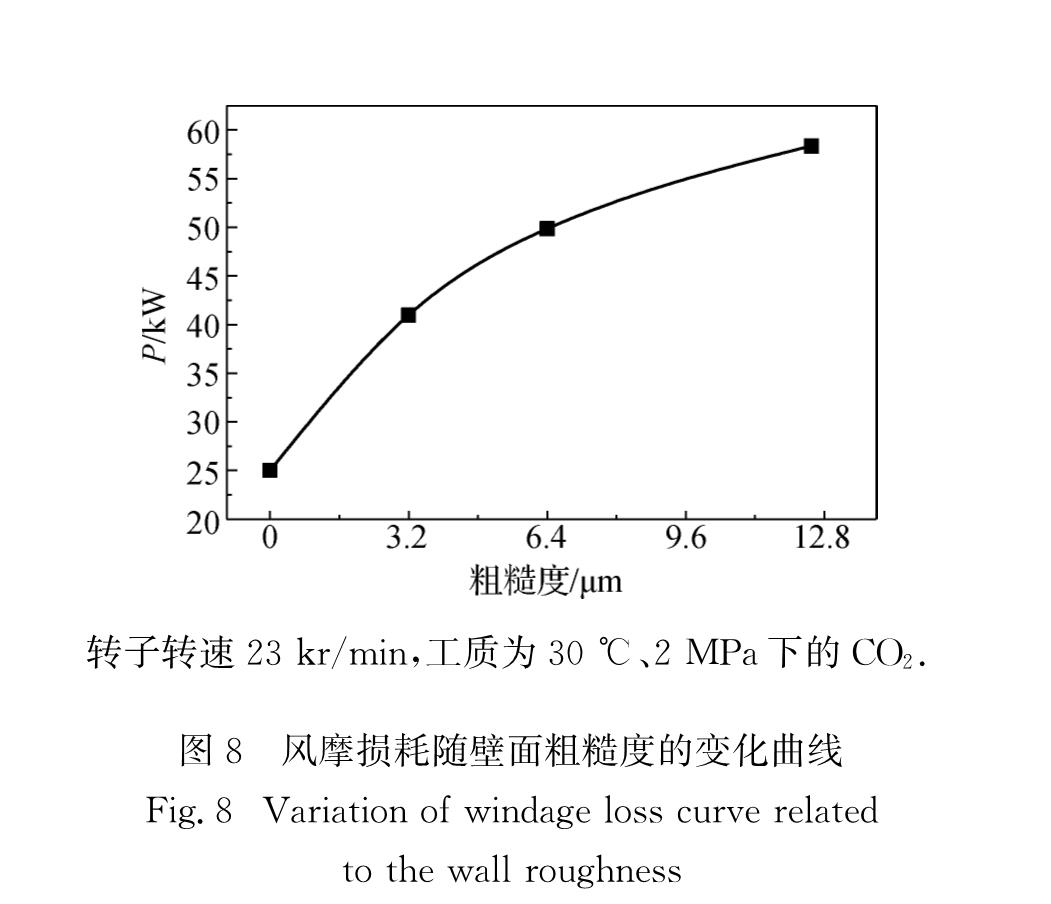

为分析不同壁面粗糙度对中高压下工质风摩损耗的影响,进一步将转子-定子壁面粗糙度分别设置为3.2,6.4和12.5 μm进行模拟计算,结果如图8所示:随着转子-定子壁面粗糙度的增加,P也逐渐增加.现有的风摩损耗预测关系式[9]未能充分考虑壁面粗糙度对风摩损耗的影响,因此在计算超临界CO2系统中涡轮机械转子的风摩损耗时,可能造成很大误差.

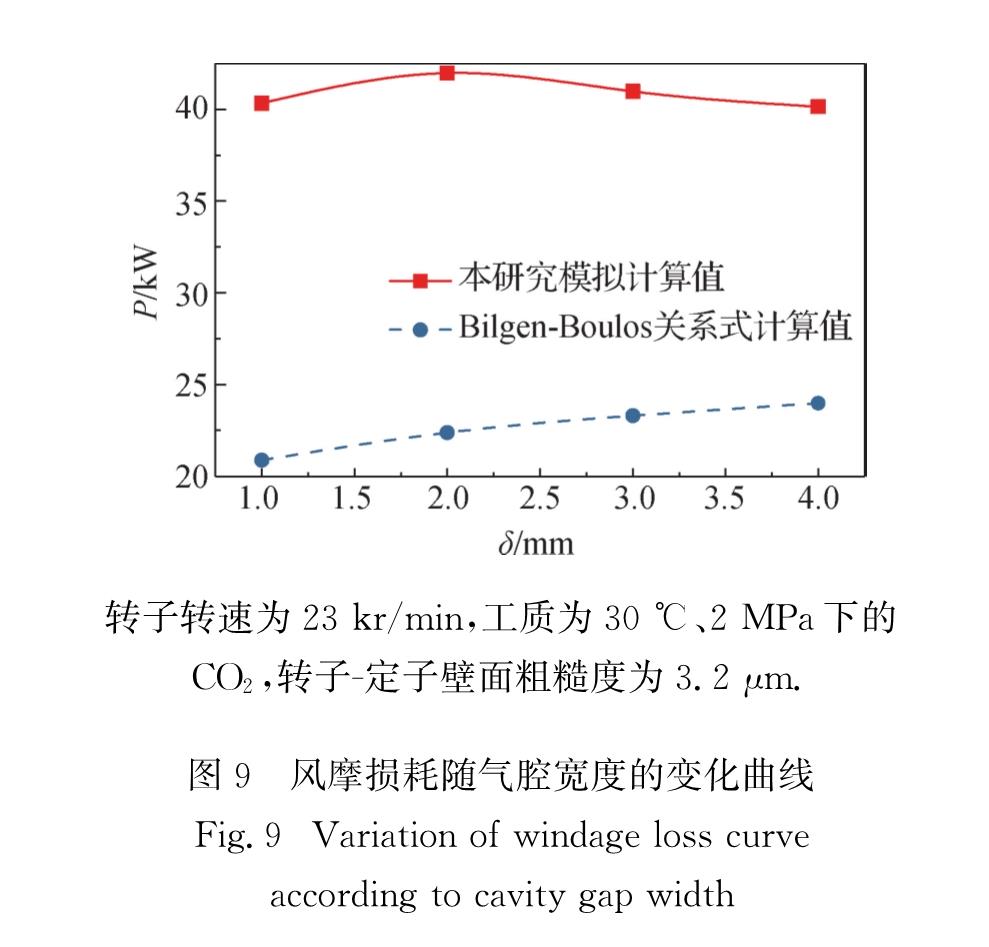

3.3 气腔宽度对风摩损耗的影响转子转速23 kr/min,工质为30 ℃、2 MPa下的CO2.

转子转速为23 kr/min,工质为30 ℃、2 MPa下的

CO2,转子-定子壁面粗糙度为3.2 μm.

通过改变定子内径的方式,分别设置气腔宽度为1,2,3,4 mm,研究气腔宽度对风摩损耗的影响.模拟结果如图9所示:P的模拟计算值随气腔宽度的增大变化不大,但其Bilgen-Boulos关系式计算值则随着气腔宽度的增大而增加,模拟计算值与Bilgen-Boulos关系式计算值相差较大,而Bilgen-Boulos关系式并未考虑壁面粗糙度对风摩损耗的影响,说明Bilgen-Boulos关系式不适用于预测2 MPa压强下非光滑壁面转子的风摩损耗.

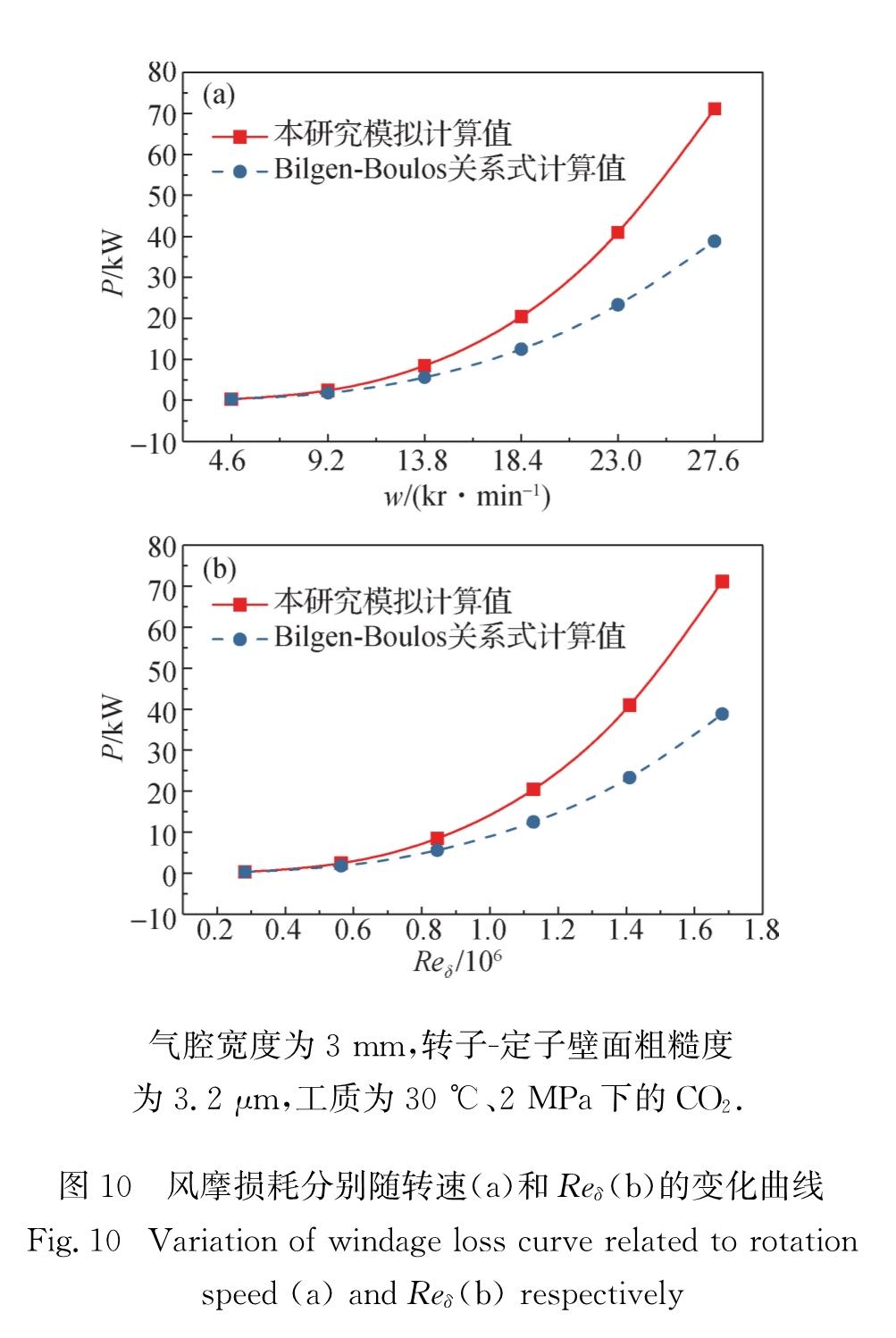

3.4 转子转速对风摩损耗的影响转子在不同转速下,Reδ不同,气腔内其与工质摩擦产生的风摩损耗也不相同.由图 10可知,当转子转速低于9.2 kr/min时,模拟计算值与Bilgen-Boulos关系式计算值间的相对误差小于±35%,可以认为在Reδ<6×105的工况下,在转子-定子壁面设置3.2 μm的粗糙度对风摩损耗的影响较小,Bilgen-Boulos关系式针对Reδ<6×105的工气腔宽度为3 mm,转子-定子壁面粗糙度

为3.2 μm,工质为30 ℃、2 MPa下的CO2.

图 10 风摩损耗分别随转速(a)和Reδ(b)的变化曲线

Fig.10 Variation of windage loss curve related to rotation speed(a)and Reδ(b)respectively况可以进行较好的预测.随着转子转速不断升高,Reδ越来越大,3.2 μm的壁面粗糙度对风摩损耗的影响逐渐增大,模拟值曲线与Bilgen-Boulos关系式计算值曲线的偏离程度也越来越大.对比结果表明,采用Bilgen-Boulos关系式对于高转速转子-定子壁面非光滑条件下风摩损耗预测的适用性差.

4 结 论

本研究通过对在2 MPa CO2工质下运行的圆柱形转子-定子腔体进行建模,分析了转子旋转摩擦工质而导致的风摩损耗问题,获得以下结论:

1)采用数值模拟方法是对涡轮机械圆柱形转子的风摩损耗问题进行研究的有效方法,在转子-定子壁面光滑条件下,模拟计算值与Bilgen-Boulos关系式和Saari实验值较为吻合,其相对误差小于±15%.

2)转子-定子壁面粗糙度对超临界CO2布雷顿循环系统中高转速以及可能出现的2 MPa较高压工况下的风摩损耗影响显著.对Reδ<6×105的工况,转子-定子壁面粗糙度处于黏性底层内,对风摩损耗的影响很小,Bilgen-Boulos关系式能对风摩损耗进行良好的预测; 对Reδ≥6×105的工况,转子-定子壁面粗糙度处于黏性底层外,对风摩损耗的影响显著,此时Bilgen-Boulos关系式对风摩损耗预测的适用性下降.

3)在以30 ℃、2 MPa的CO2作为工质,转速23 kr/min 的工况下,风摩损耗随着转子-定子壁面粗糙度和转子转速的增加而增加; 气腔宽度的变化未对风摩损耗造成明显影响.

- [1] WENDT F.Turbulente Strömungen zwischen zwei rotierenden konaxialen zylindern[J].Ingenieur-Archiv,1933,4(6):577-595.

- [2] TAYLOR G I.Fluid friction between rotating cylinders.Ⅰ.Torque measurements[J].Proceedings of the Royal Society of London Series A:Mathematical and Physical Sciences,1936,157(892):546-564.

- [3] PANTELL K.Versuche über scheibenreibung[J].Forschung auf dem Gebiete des Ingenieurwesens,1949,16(4):97-108.

- [4] DONNELLY R J.Experiments on the stability of viscous flow between rotating cylinders.Ⅲ.Enhancement of stability by modulation[J].Proceedings of the Royal Society of London Series A:Mathematical and Physical Sciences,1964,281(1384):130-139.

- [5] DONNELLY R J,SIMON N J.An empirical torque relation for supercritical flow between rotating cylinders[J].Journal of Fluid Mechanics,1960,7(3):401-418

- [6] YAMADA Y.Torque resistance of a flow between rotating co-axial cylinders having axial flow[J].Bulletin of JSME,1962,5(20):634-642.

- [7] YAMADA Y.Resistance of a flow through an annulus with an inner rotating cylinder[J].Bulletin of JSME,1962,5(18):302-310.

- [8] VRANCIK J E.Prediction of windage power loss in alternators[R].Ohio:Lewis Research Center,1968.

- [9] BILGEN E,BOULOS R.Functional dependence of torque coefficient of coaxial cylinders on gap width and Reynolds numbers[J].Journal of Fluids Engineering,1973,95(1):122-126.

- [10] SAARI J.Thermal analysis of high-speed induction machines[D].Helsinki:Helsinki University of Technology,1998:19-26.

- [11] WRIGHT S A,RADEL R F,VERNON M E,et al.Operation and analysis of a supercritical CO2 Brayton cycle[R].Albuquerque:Sandia National Laboratories,2010.doi:10.2172/984129.

- [12] 邢军强,王凤翔,张殿海,等.高速永磁电机转子空气摩擦损耗研究[J].中国电机工程学报,2010,30(27):14-19.

- [13] 汪东欣.大型主氦变频驱动电机电磁设计方法研究与强度校核[D].哈尔滨:哈尔滨理工大学,2012:13-16.

- [14] 丁树业,郭长光,郭保成,等.双馈水轮发电机风摩损耗数值研究[J].华中科技大学学报(自然科学版),2014,42(2):26-30.

- [15] 张凤阁,杜光辉,王天煜,等.兆瓦级高速永磁电机通风系统设计与转子表面风摩耗研究[J].电机与控制学报,2014,18(2):50-55.

- [16] 刘光伟,赵新刚,张凤阁,等.高速永磁爪极电机铁耗与空气摩擦损耗计算[J].电工技术学报,2015,30(2):148-154.

- [17] 李玉超.280 kW高速感应电动机的设计与分析[D].沈阳:沈阳工业大学,2015:25-28.

- [18] 李忠雨.感应电动机温升敏感性因素分析与优化[D].哈尔滨:哈尔滨理工大学,2016:25-29.

- [19] 程文杰,李维,钟斌,等.高速电机定转子小间隙强迫风冷却数值模拟[J].微特电机,2018,46(11):6-11.