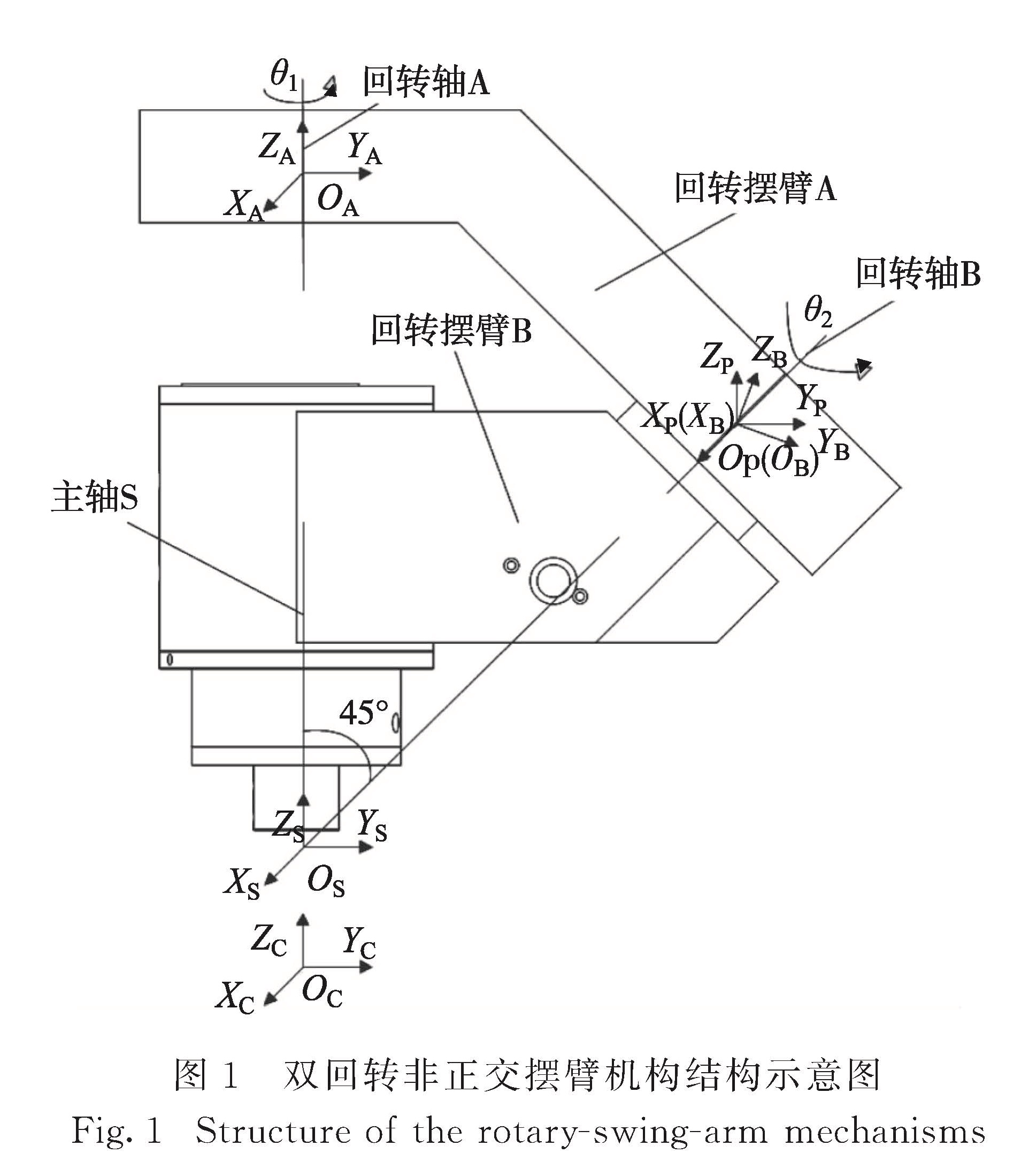

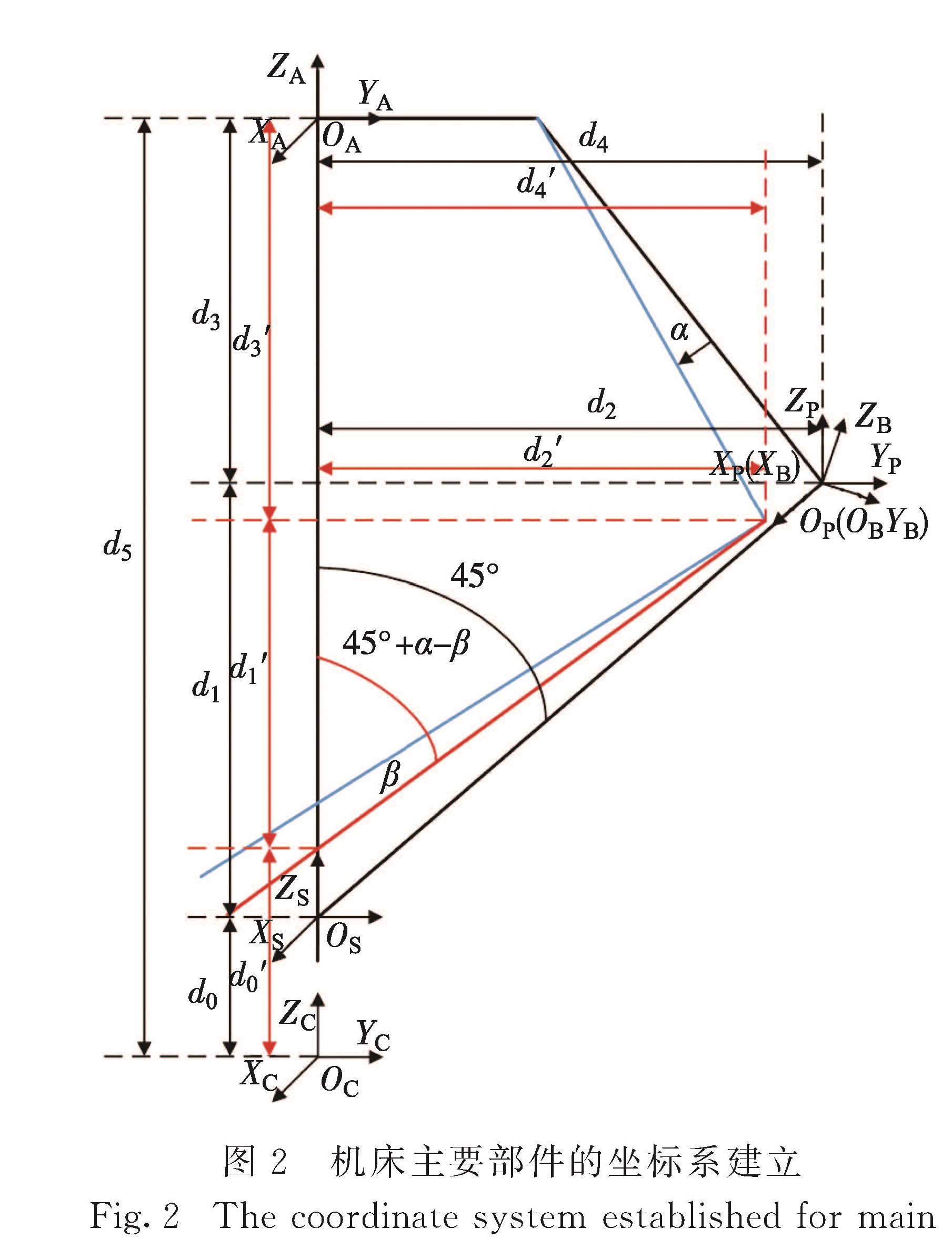

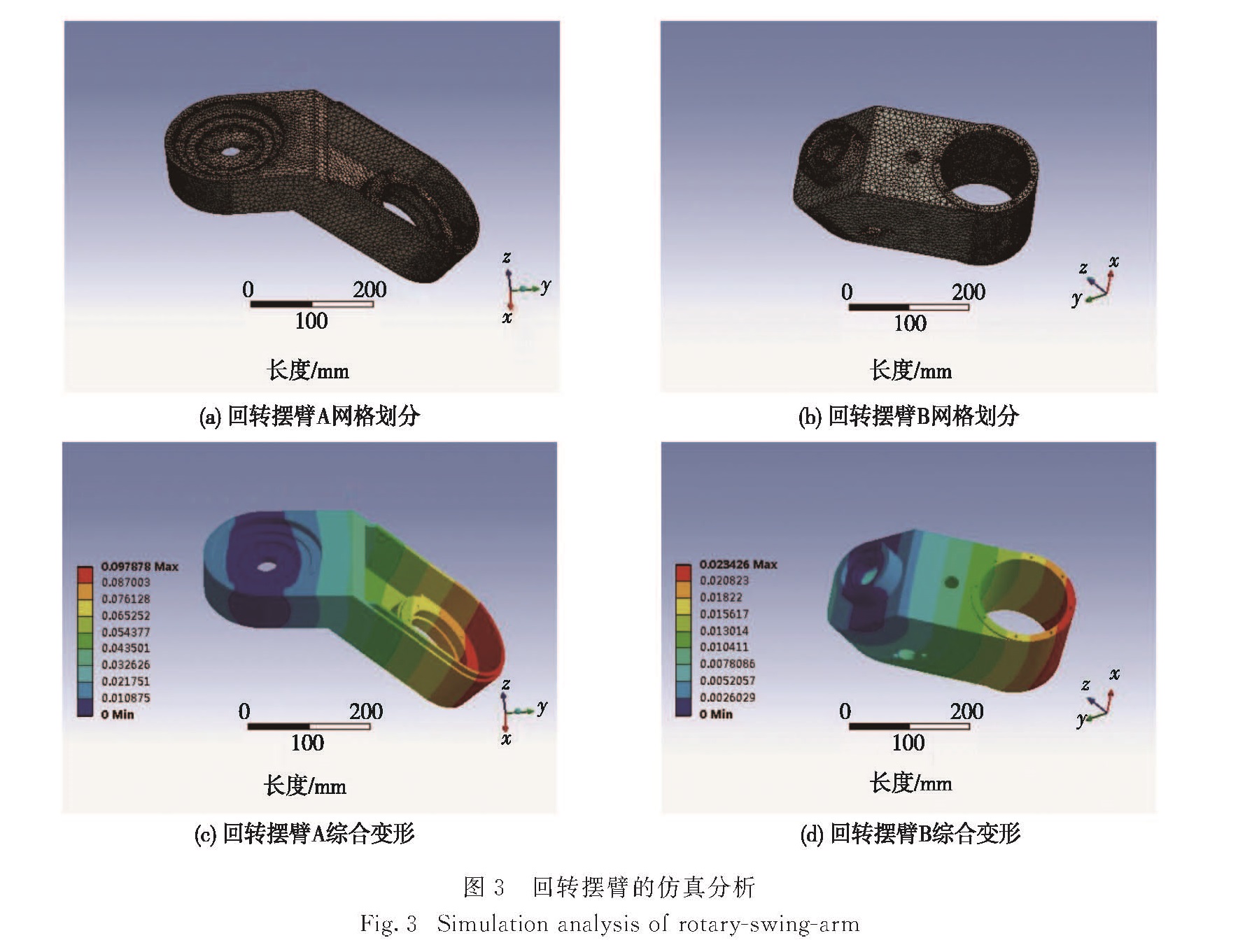

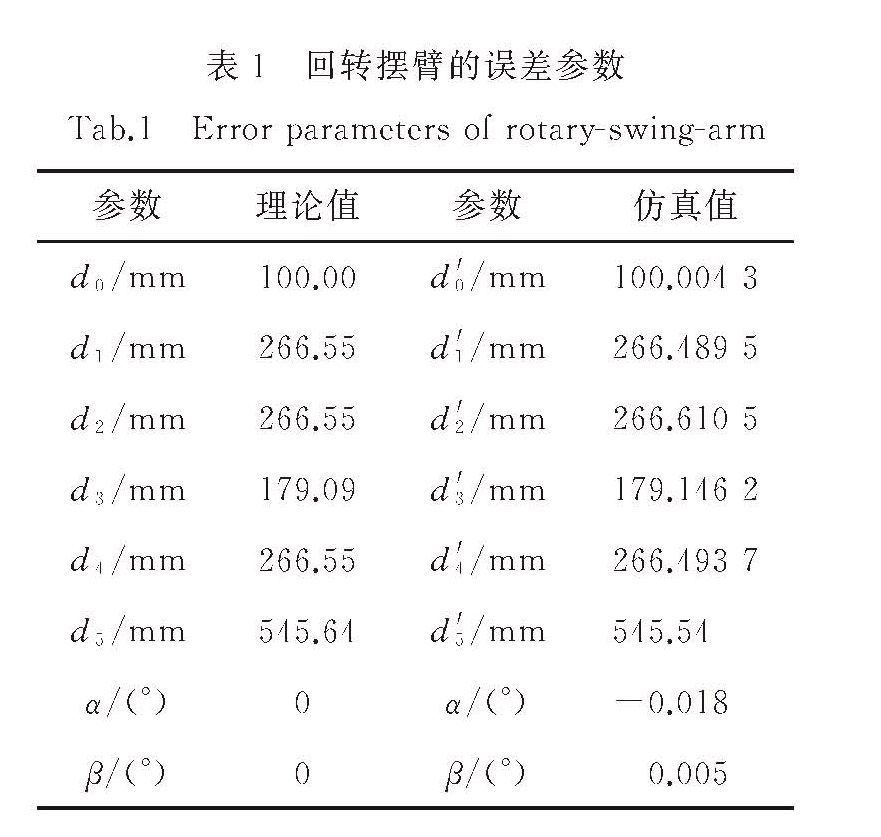

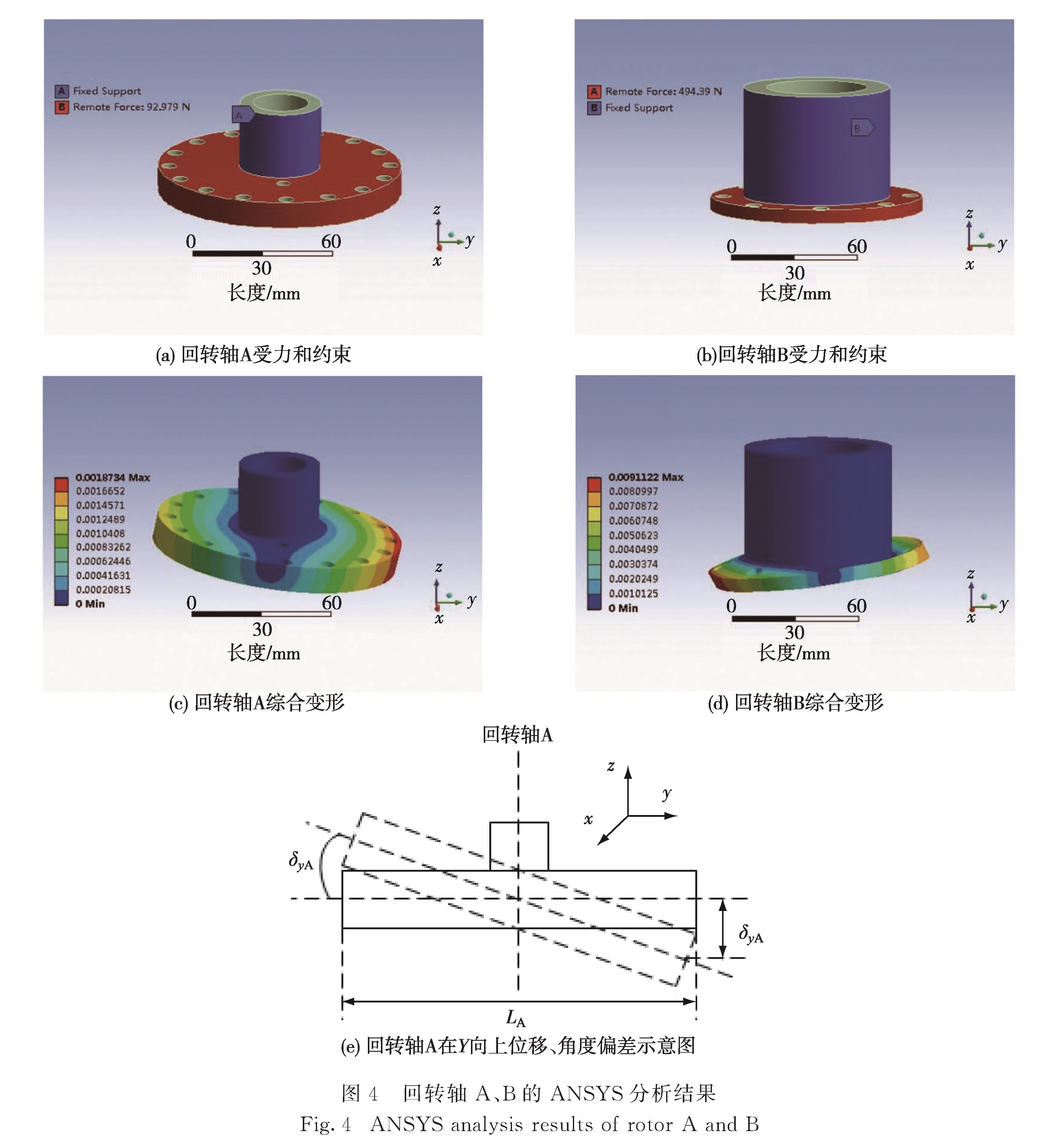

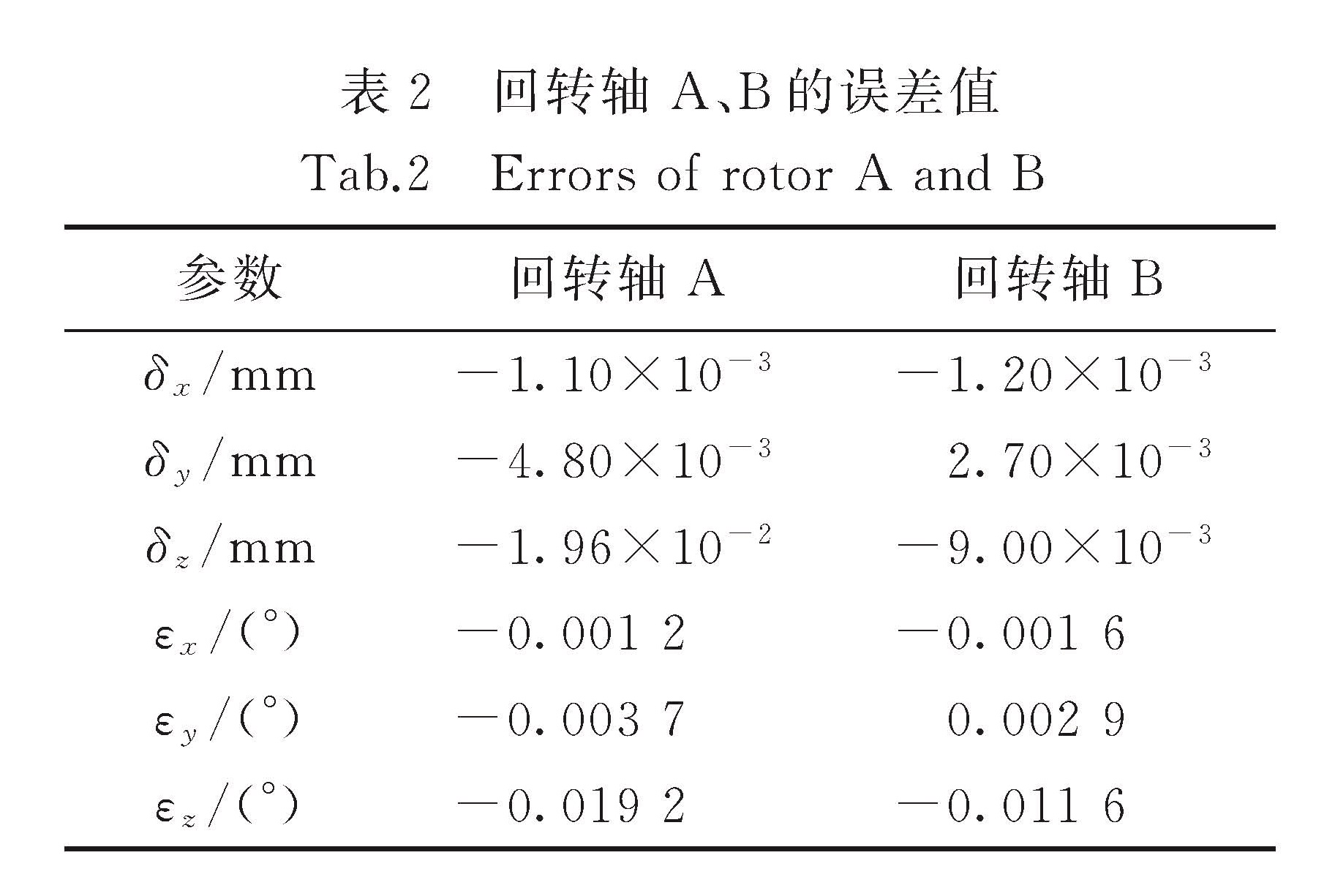

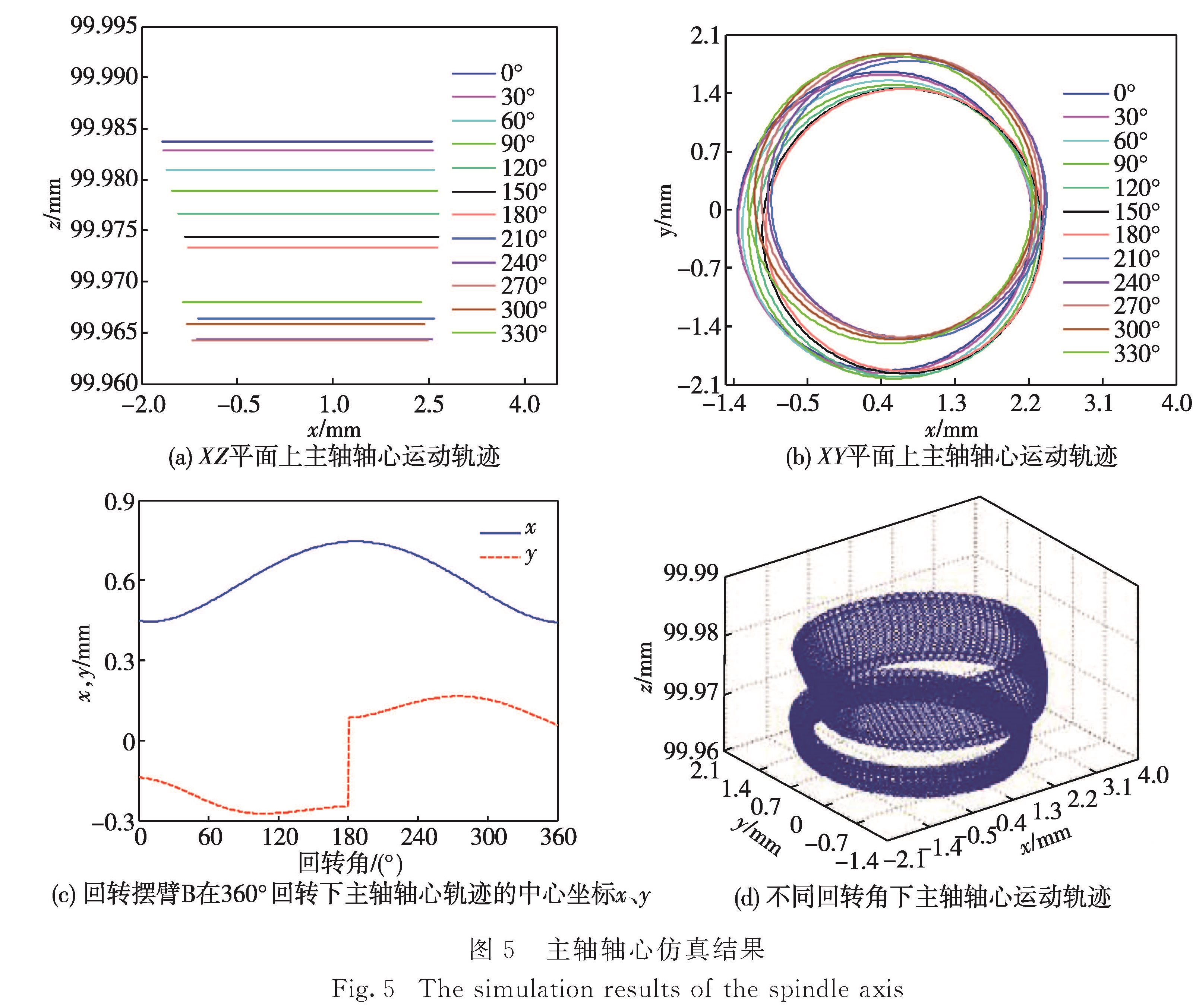

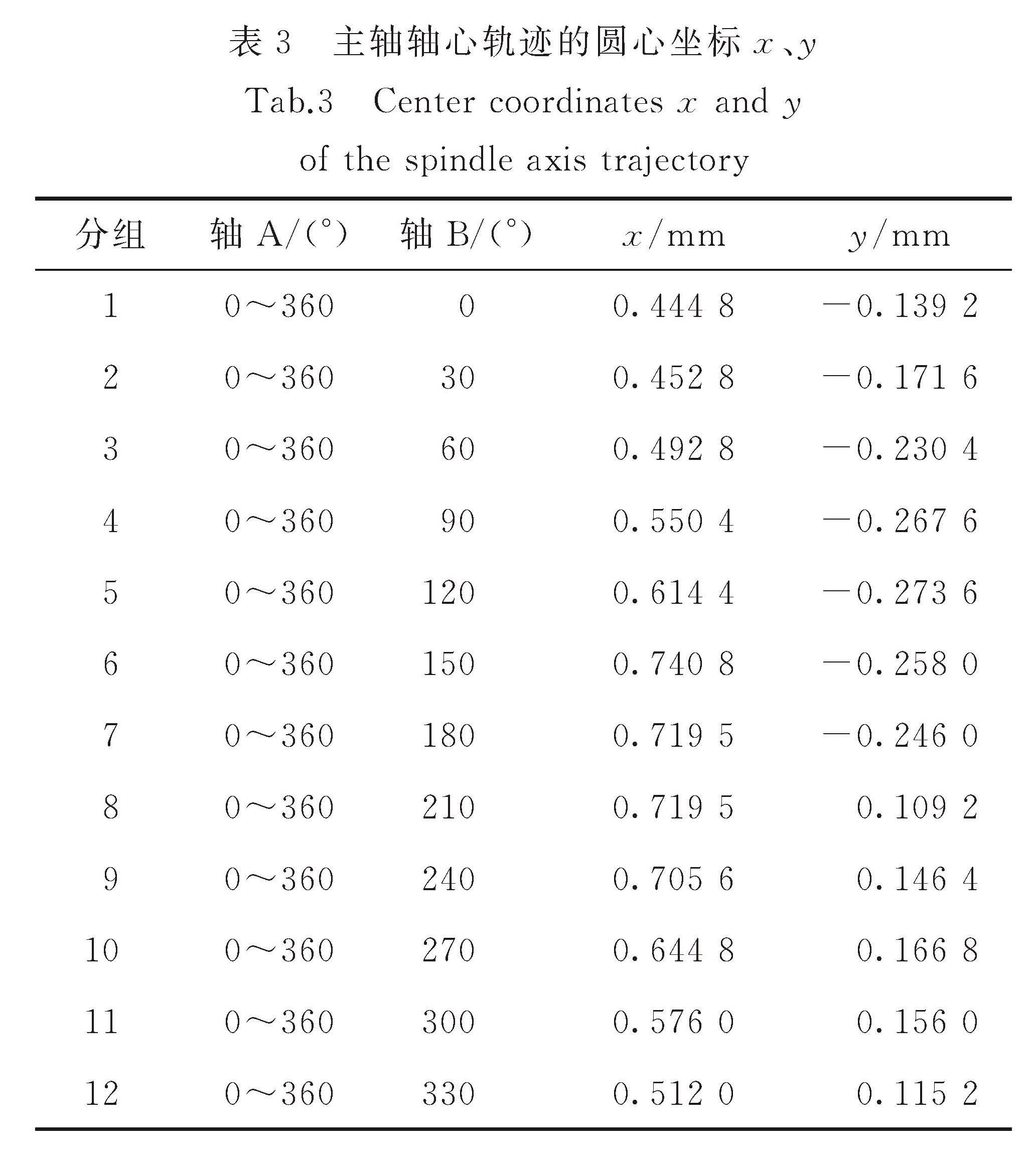

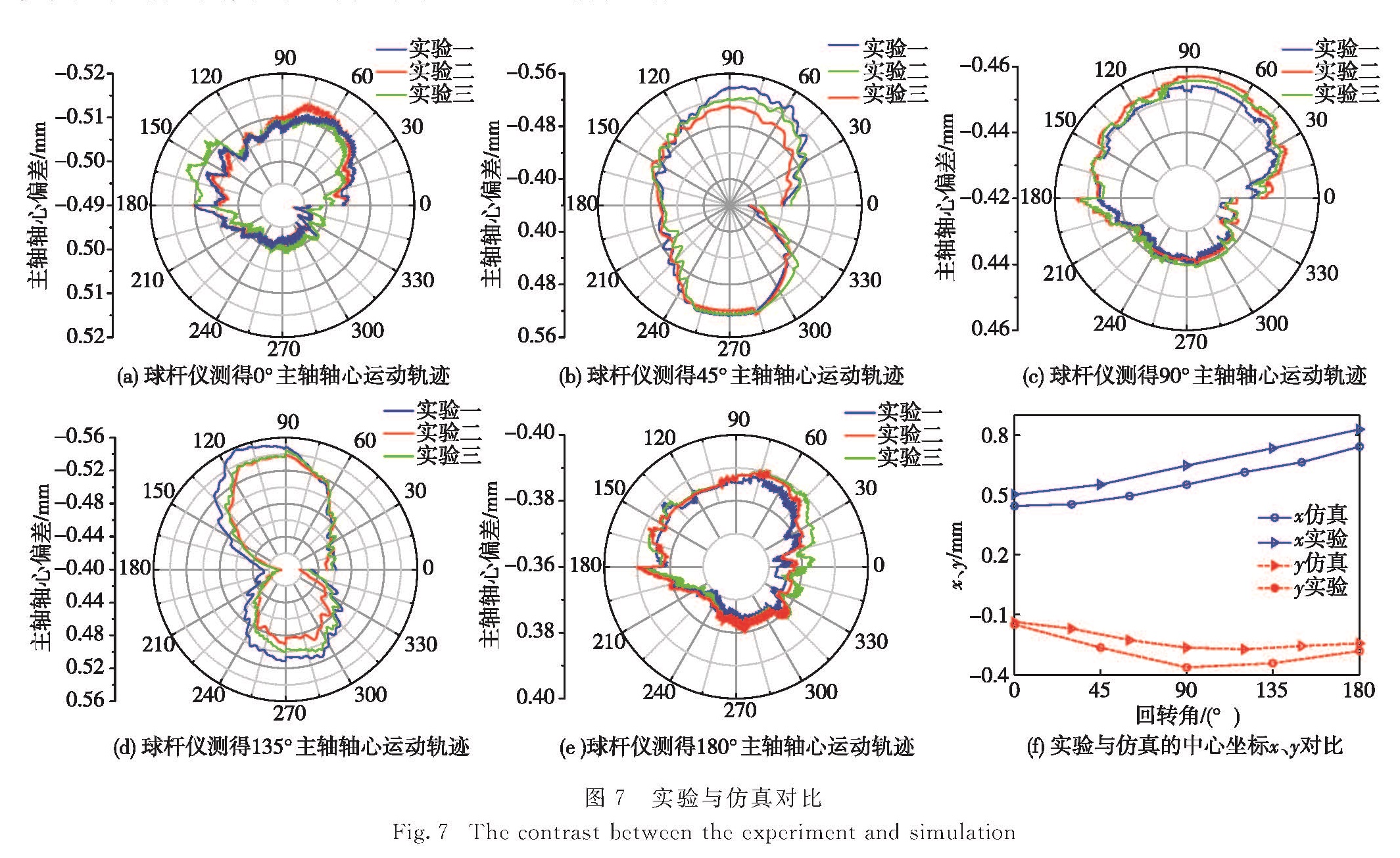

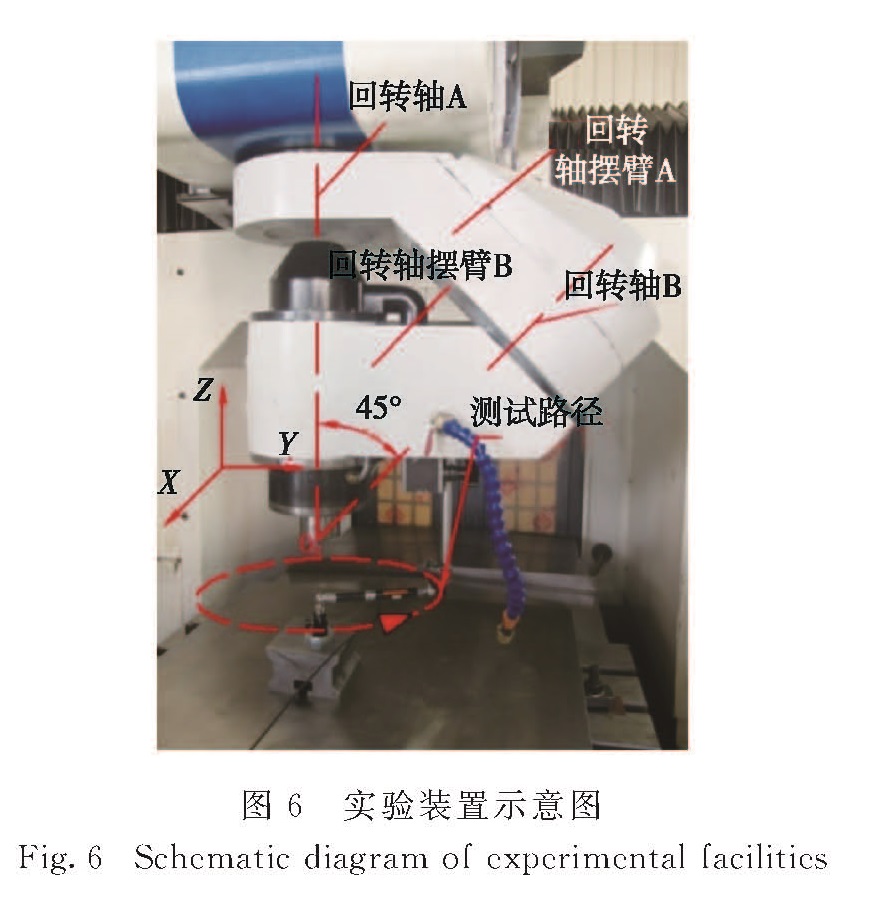

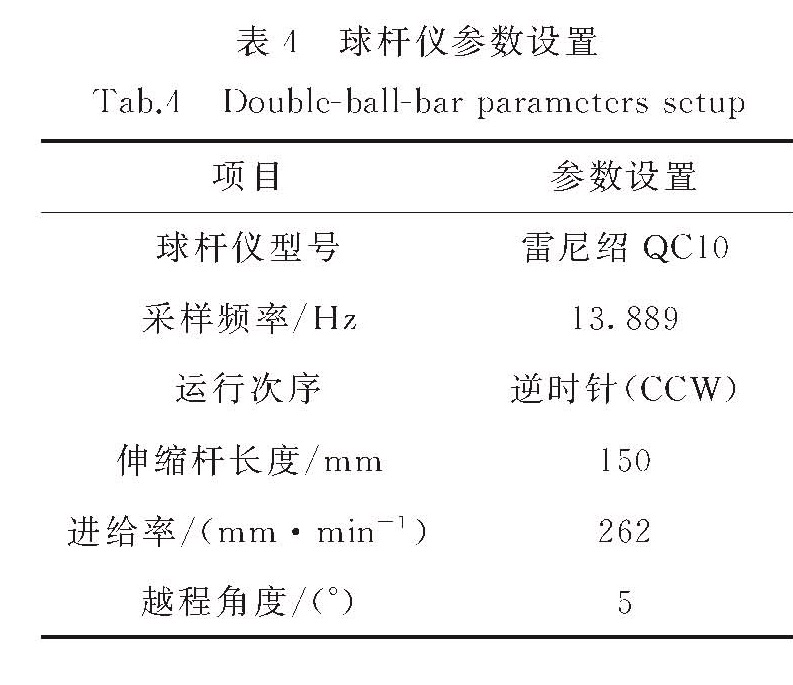

非正交双回转摆臂机构回转范围广、灵活性强,能实现复杂曲面的加工.但该类型回转摆臂机构的主轴轴心偏差会直接影响被加工工件的面形精度.为了有效分析并测量出主轴轴心偏差进而改善机床精度,基于多体系统理论建立了非正交双回转摆臂机构的主轴轴心运动误差模型,此模型包含了回转轴A、B各6项静态结构误差; 通过对此运动误差模型进行ANSYS静态仿真分析,获得了回转摆臂机构B在不同回转角度下主轴轴心的运动轨迹; 基于Renishaw公司开发的QC10球杆仪测量原理设计了5种不同实验测量路径,验证了主轴轴心运动误差模型可用于非正交回转机构主轴轴心的误差辨识.

Non-orthogonal mechanisms of double rotary-swing-arm have widely rotation ranges,good flexibility,and they can accomplish the machining of complex surface.However,the deviation of the spindle axis caused by this type of rotary-swing-arm mechanism will directly affect the surface accuracy of the machined work-piece.For the purpose of improving the accuracy of such a mechanism,it is necessary to analyze and measure the deviation value of the spindle axis.In this paper,a kinematic-error mathematical model based on multi-body system theory is established for analyzing the spindle axis deviation of non-orthogonal double rotary-swing-arm mechanisms,which take rotation axis A and B with each axis of six static deviations into consideration.Through the ANSYS static simulation analysis and the mathematical expression of kinematic errors model,the spindle axis trajectory of rotary-swing-arm B in different rotation angle situation can be obtained.Based on the measurement principle of Renishaw company QC10 instrument,five different measurement paths are designed. Combined with experiment results,the spindle axis deviation can be achieved quickly.By experimentation,this kinematic errors model of spindle axis is effective,and may be used to identify the spindle axis deviation of non-orthogonal rotary-swing-arm mechanism.In order to find out the suitable processing rotation angle,we evaluate trajectory trends of the deviation of rotary-swing-arm mechanism spindle axis.Therefore,the machining precision and surface quality of work piece can be improved,and the good process ability of non-orthogonal mechanism can be elevated.