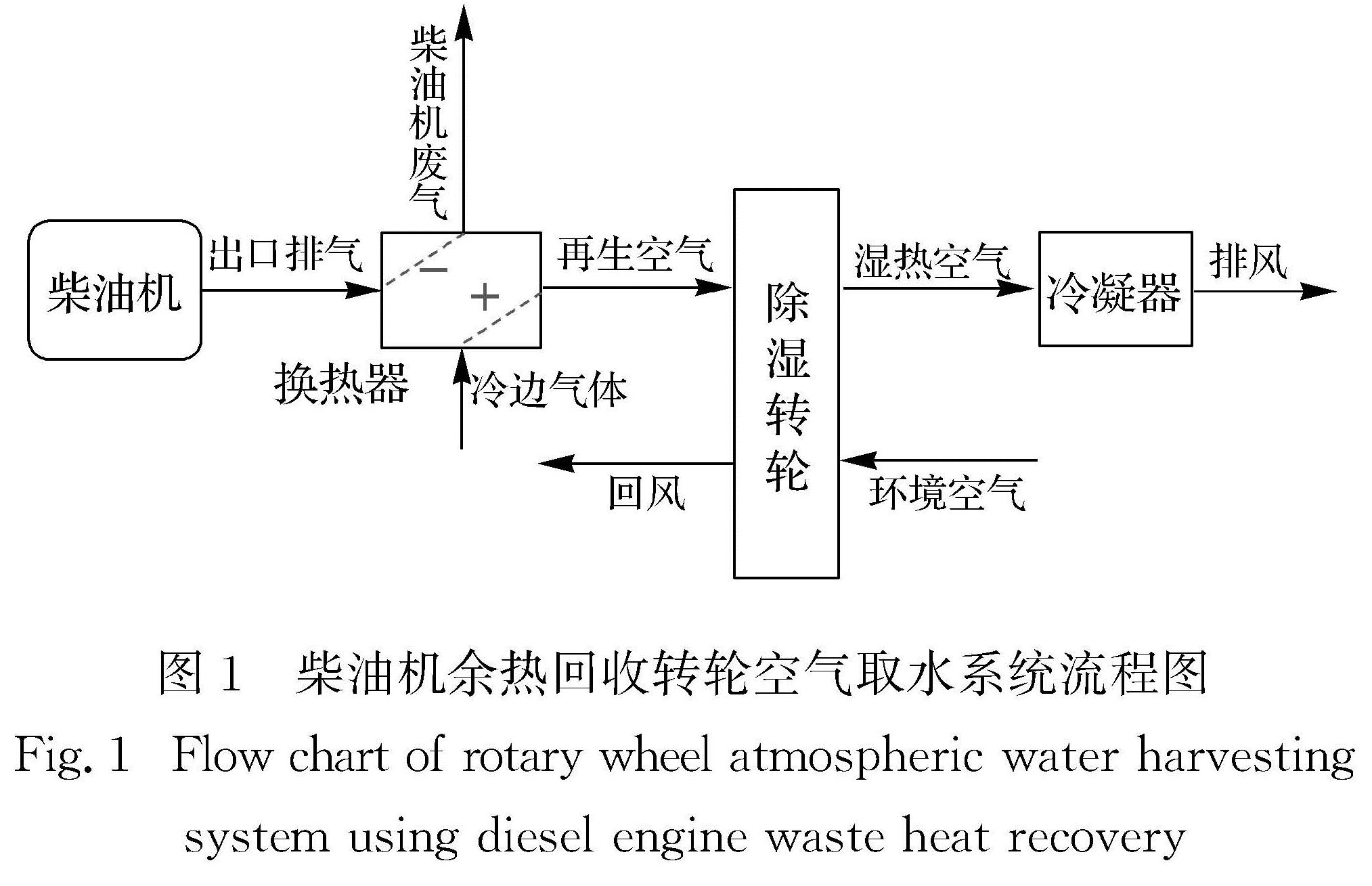

Objective: The rotary atmospheric water harvesting system combining the desiccant wheel and diesel engine can use waste heat of the latter to heat the regenerated air which is then pumped into the desiccant wheel, thereby improving the energy utilization efficiency However, the common one-dimensional model of the desiccant wheel at present includes partial differential equations, which is inefficient to participate in the system-level simulation. In this paper, a distributed parameter desiccant wheel model composed of ordinary differential equations is established and applied to the study of the dynamic characteristics of rotary atmospheric water harvesting system.

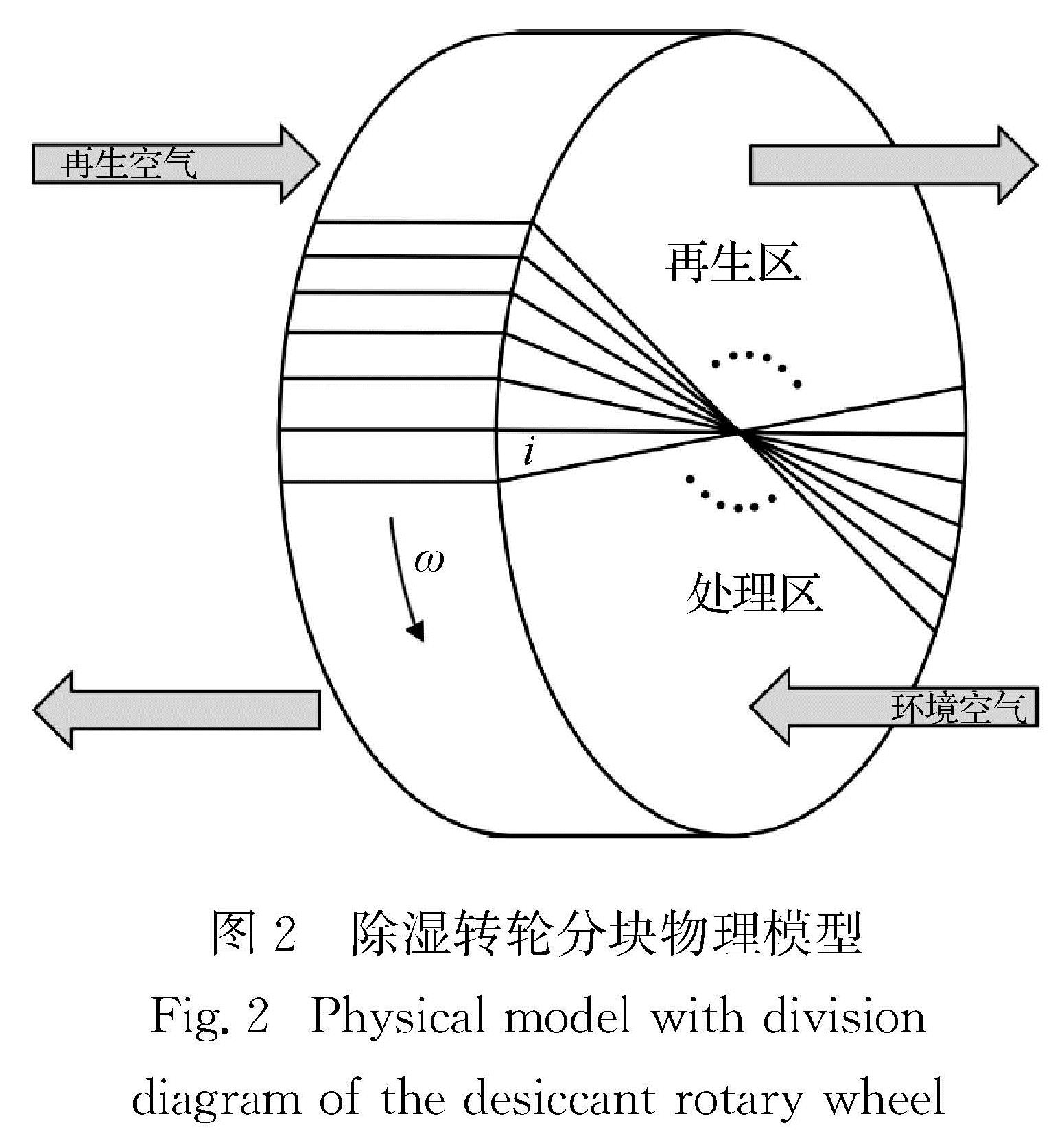

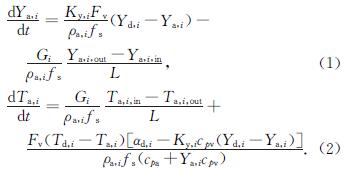

Methods: The desiccant wheel was equally divided into 40 small sectors. Based on the moisture mass and energy conservation of the gas side and the adsorbent side in its operation process, a mathematical model was formed. The diesel engine model was established according to the thermodynamic and dynamic characteristics of diesel engine, and transfer functions were applied to express the pulse width and torque variation delay, respectively. A proportion integral differential (PID) controller was used to regulate electronic governor. The plate-fin heat exchanger was used to recover the exhaust heat of diesel engine with the ambient air as cold side gas and the exhaust gas from the outlet of diesel engine as hot side gas.

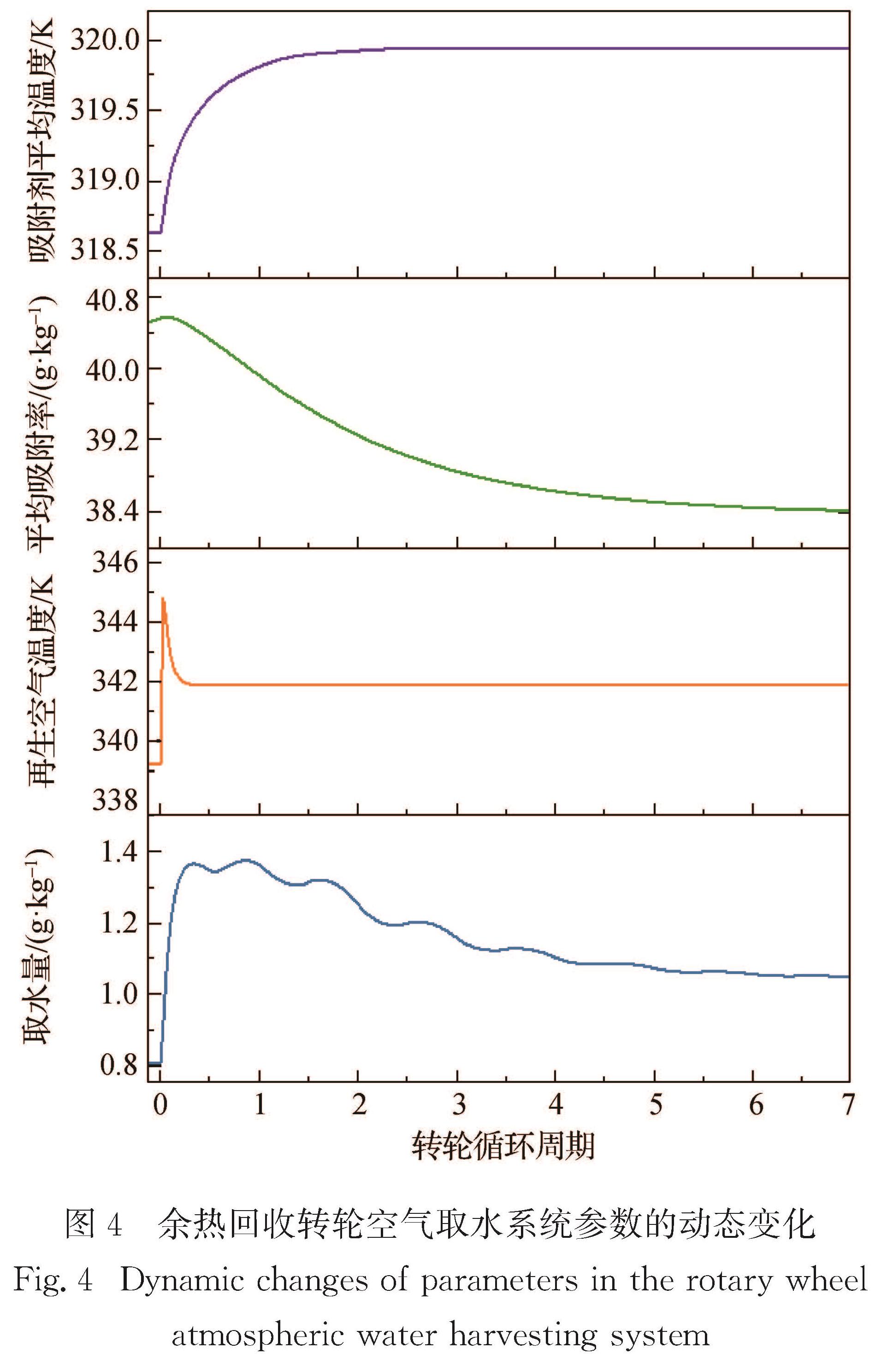

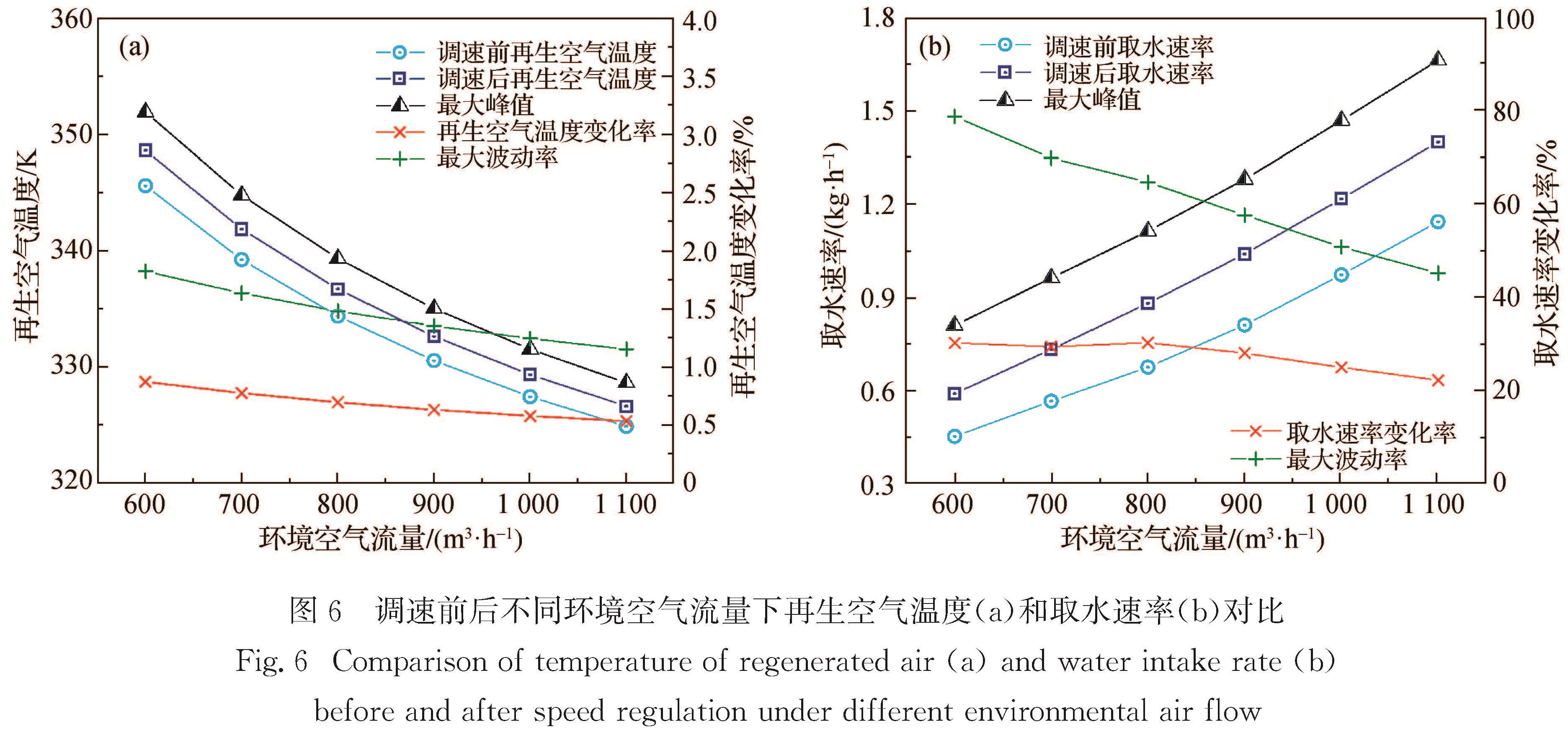

Results: Compared with the operation results of lumped and distributed parameter models in this steady state, the results of two models fit well and the results of distributed parameter model could accurately reflect the characteristics of adsorbent parameters. As the speed increased, the changes of the four parameters were all small. Among them, it took a longer time (6-7 cycles) for the desiccant wheel water harvesting amount and adsorbent adsorption rate to become stable, in which the former was more stable than the latter, whereas the temperature of the regenerated air reached a stable state within 0.5 cycles. At the same time, the variation range of the water harvesting amount of the desiccant wheel and the temperature of the regenerated air was relatively large in the early stage. The results showed that the average temperature of adsorbent was directly affected by the temperature of regeneration air, and the influence had a time lag. With the increase of ambient air flow rate, the temperature of the regenerated air obtained by waste heat recovery kept decreasing, and the change rates caused by the increase of diesel engine speed were all from 0.50% to 1.00%, and gradually tended to be flat. As for the water harvesting rate of the desiccant wheel, the speed increase of the diesel engine had a great influence. When the air flow rate was between 600 and 800 m3/h, the change rate was close to or reached 30%, but the influence degree also decreased with the increase of the air flow rate. In general, when the air flow rate of the desiccant wheel is large, the stability of the system is better under off-design conditions.

Conclusion: When the speed of the diesel engine increased, the time required for the water harvesting amount of the desiccant wheel and the adsorption rate of the adsorbent to stabilize again was relatively long (6 to 7 cycles of the rotating wheel). For the dynamic characteristics of atmospheric water harvesting system, the water harvesting amount was greatly affected by the temperature of the regeneration air of the desiccant wheel, and both changed greatly in the early stage when the diesel engine speeded up. When the inlet air flow rates of the desiccant wheel treatment area and the regeneration area were equal, the air flow rate change had limited influence on the cycle times required for the system to reach a stable state again after the diesel engine speeded up. Meanwhile, the stability of the system was better under off-design conditions when the flow rate was large. When the ambient air flow rate was higher than 1000 m3/h, the temperature of the regenerated air obtained from waste heat recovery was relatively low. The operation stability of the system under off-design conditions was poor when the flow rate was lower than 800 m3/h. Therefore, the ambient air flow rate should be maintained at 800-1000 m3/h.

空气取水能够有效解决野外作业期间的供水问题.本文建立由常微分方程组构成的分布参数除湿转轮模型,搭建柴油机余热回收空气取水模型,研究柴油机工况变化过程中取水系统的动态工作状况.结果表明:在柴油机目标转速提高时,转轮取水量和吸附剂吸附率较再生空气和吸附剂温度稳定所需时间更长,需转轮循环工作6~7个周期后重新稳定; 取水量受再生空气温度影响较大; 在转轮环境空气流量较大时,系统变工况下运行稳定性更好.为保证系统高取水速率与稳定性,环境空气流量应维持在800~1 000 m3/h.本文模型可用于进一步研究转轮空气取水系统的控制与运行优化.