Objective: The maraging steel PH 13-8 Mo has been widely used in the industrial fileds of medical, aerospace and automotive etc. attributed to its stable and excellent mechanical properties provided by dispersive nano size precipitates. For the critical service environment of nuclear application, these nano-sized second-phase particles in materials will evolve along with the accumulation of irradiation damage induced by neutron flux, which would degrade the mechanical properties of alloys and result in components failure. In this work, the stability and evolution behavior of NiAl precipitates after ion beam irradiation were examined and analysis was carried out to establish the relationship between the size of nano precipitates and irradiation damage. In addition, transmission electron microscope (TEM) observation with selected g vectors was conducted to reveal more information about the irradiation induced dislocation.

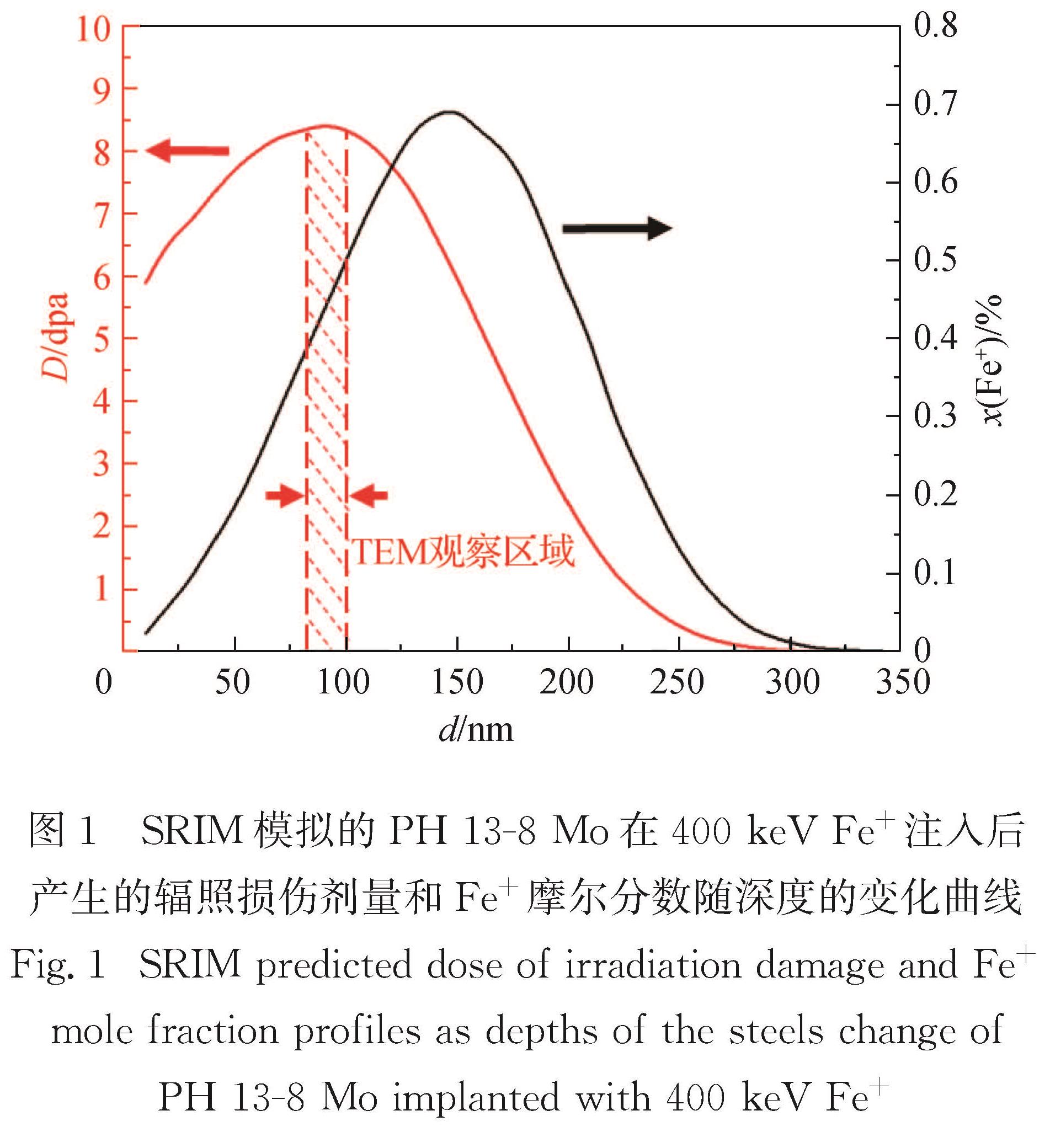

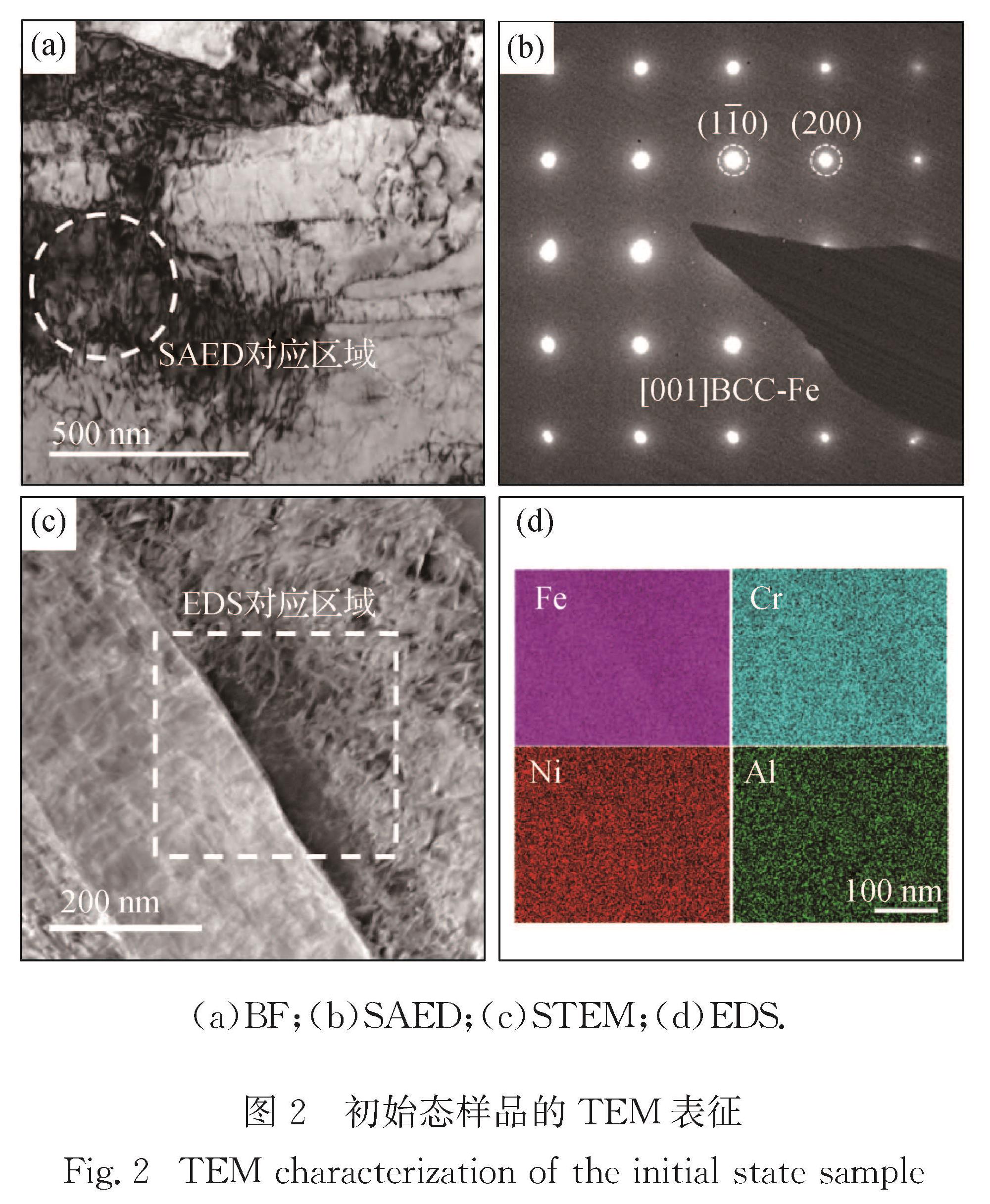

Methods: The flake samples were aged at 450, 475 and 500℃, respectively, for 20 h and then cooled with the furnace. Subsequently, samples were prepared as Φ 3 mm discs and twin-jet electropolished. The prepared Φ 3 mm foils were characterized with TEM, and then were ex-situ irradiated with 400 keV Fe+ ion beams at an NEC (National Electronic Corporation) implanter with total fluence as 3.33×1015 ions/cm2 at room temperature. The conventional bright-field (BF) observation, high-resolution transmission electron microscopy (HRTEM) images and resultant fast Fourier transformation (FFT) were used to analyze the precipitates. Scanning transmission electron microscope (STEM) and energy dispersive spectroscopy (EDS) were used to analyze the element segregation of precipitates. ImageJ and manual counting methods were used to measure the size and to count the number density of precipitates and dislocations from dark field (DF) images and BF TEM images.

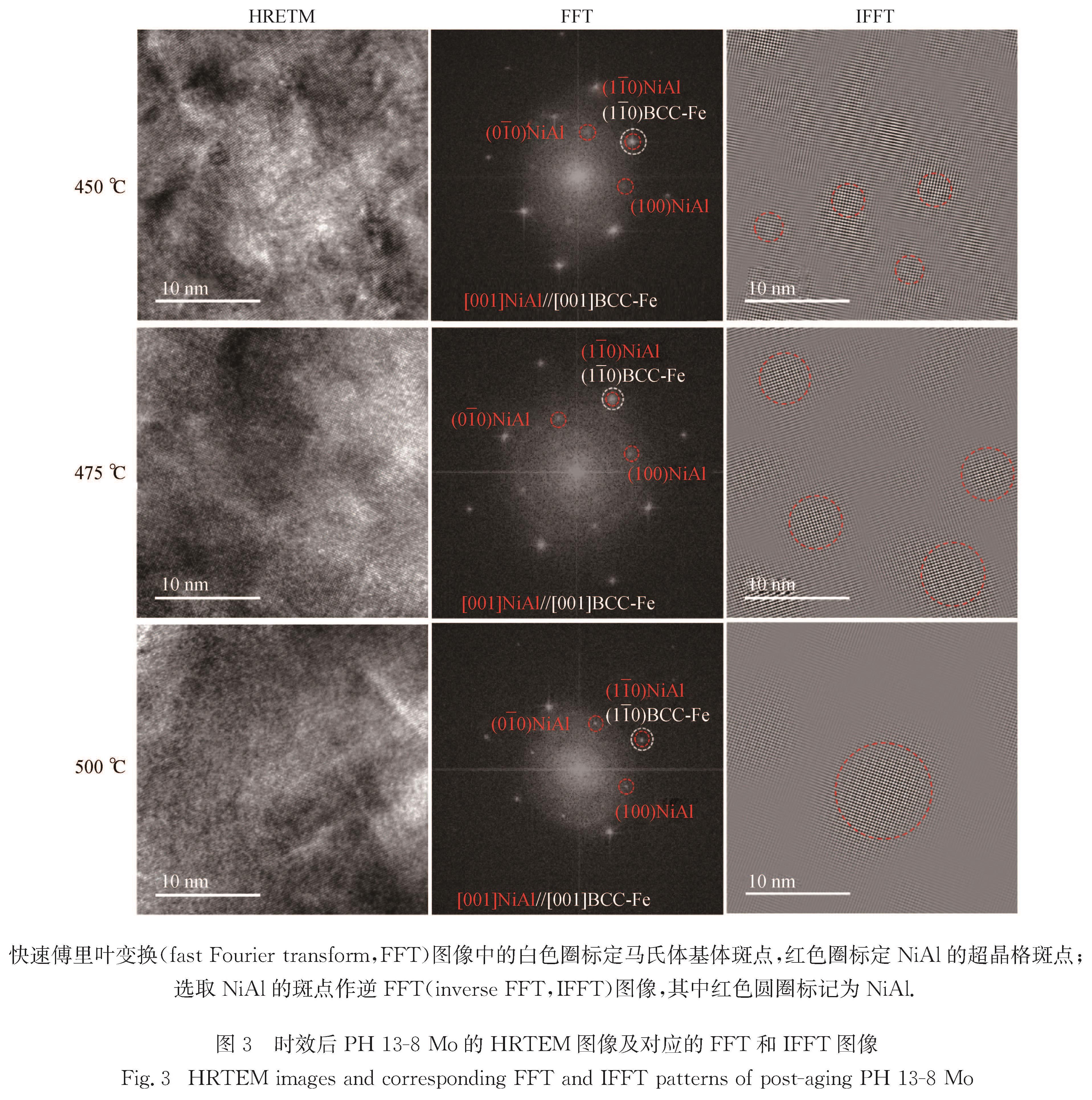

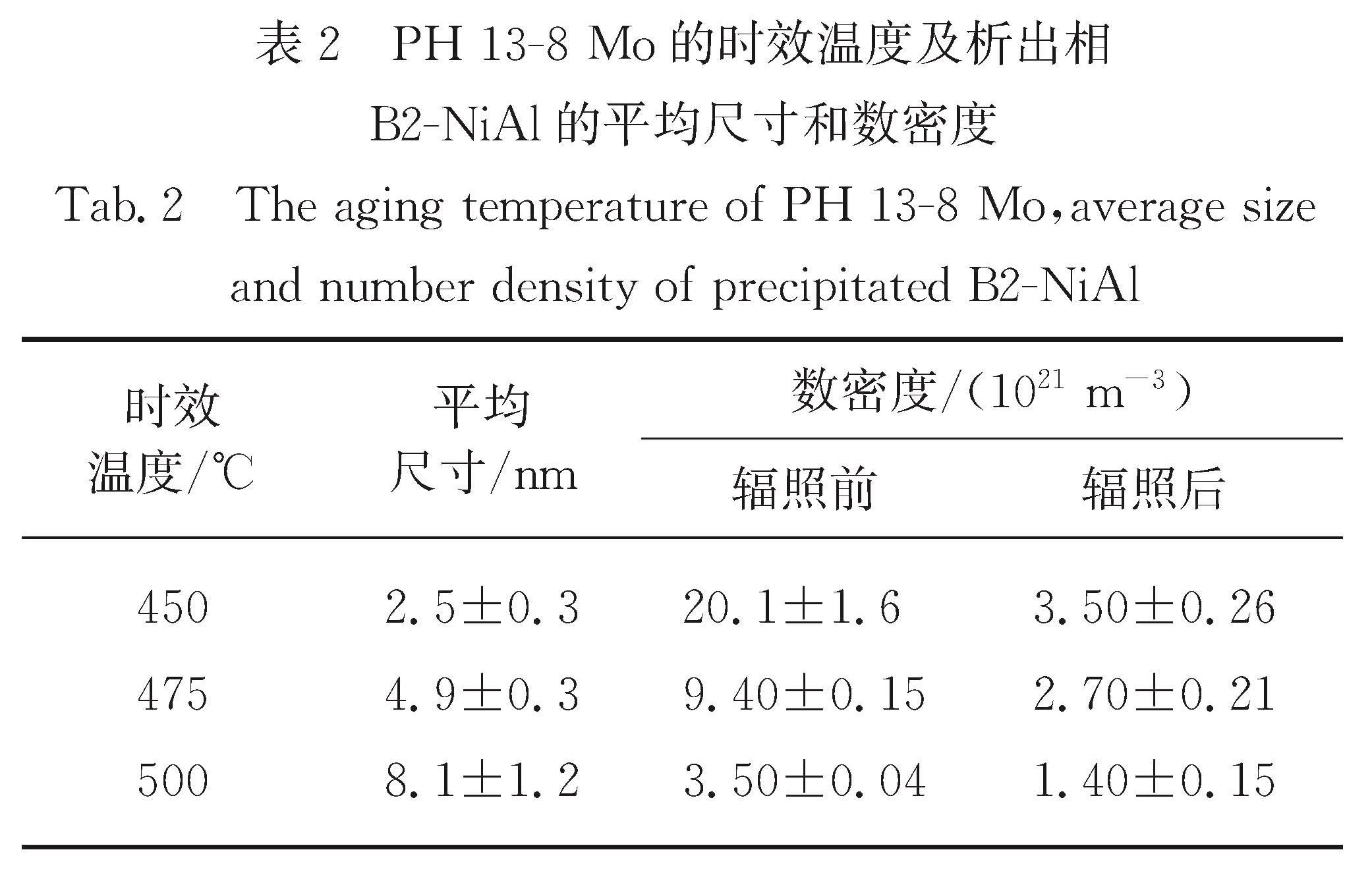

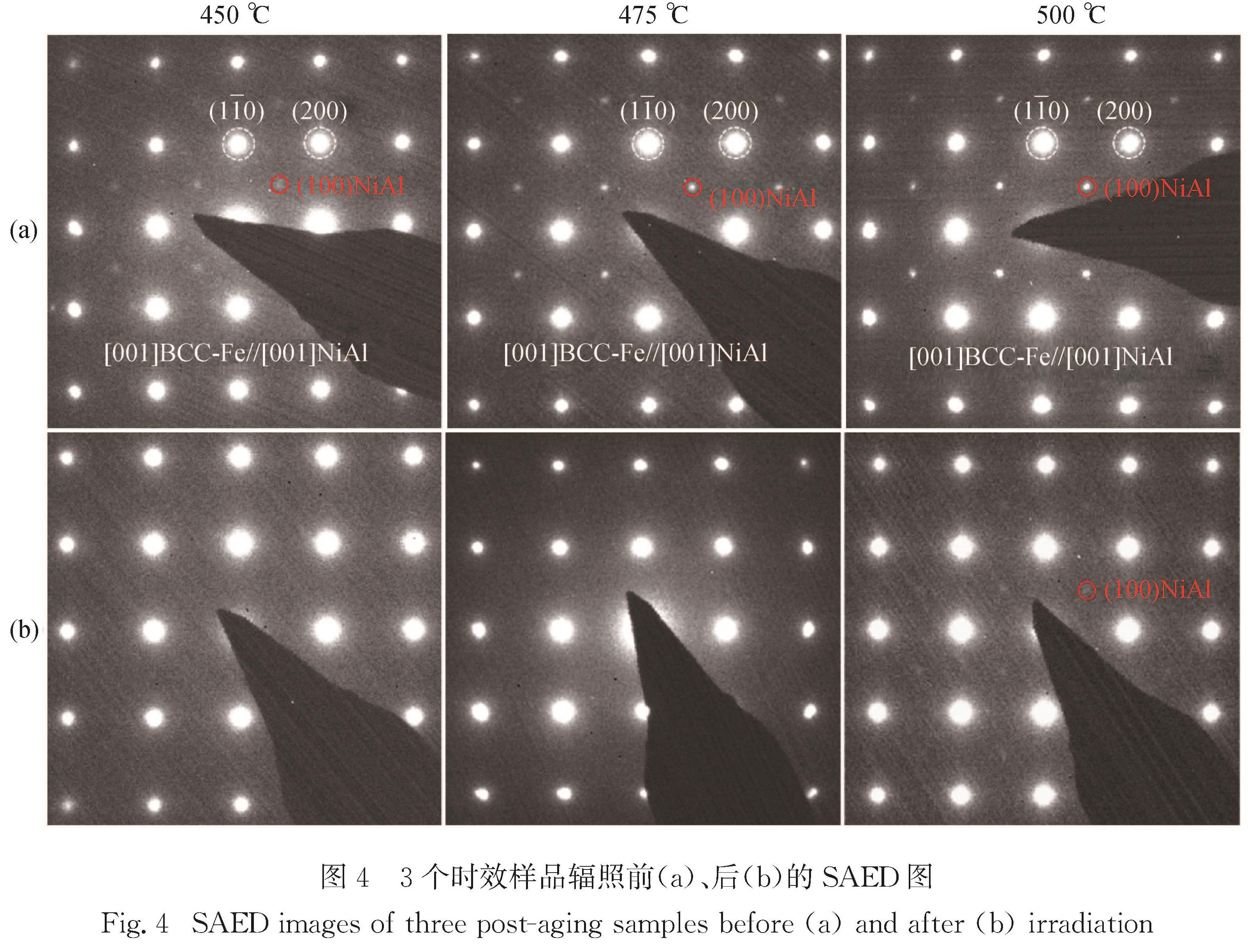

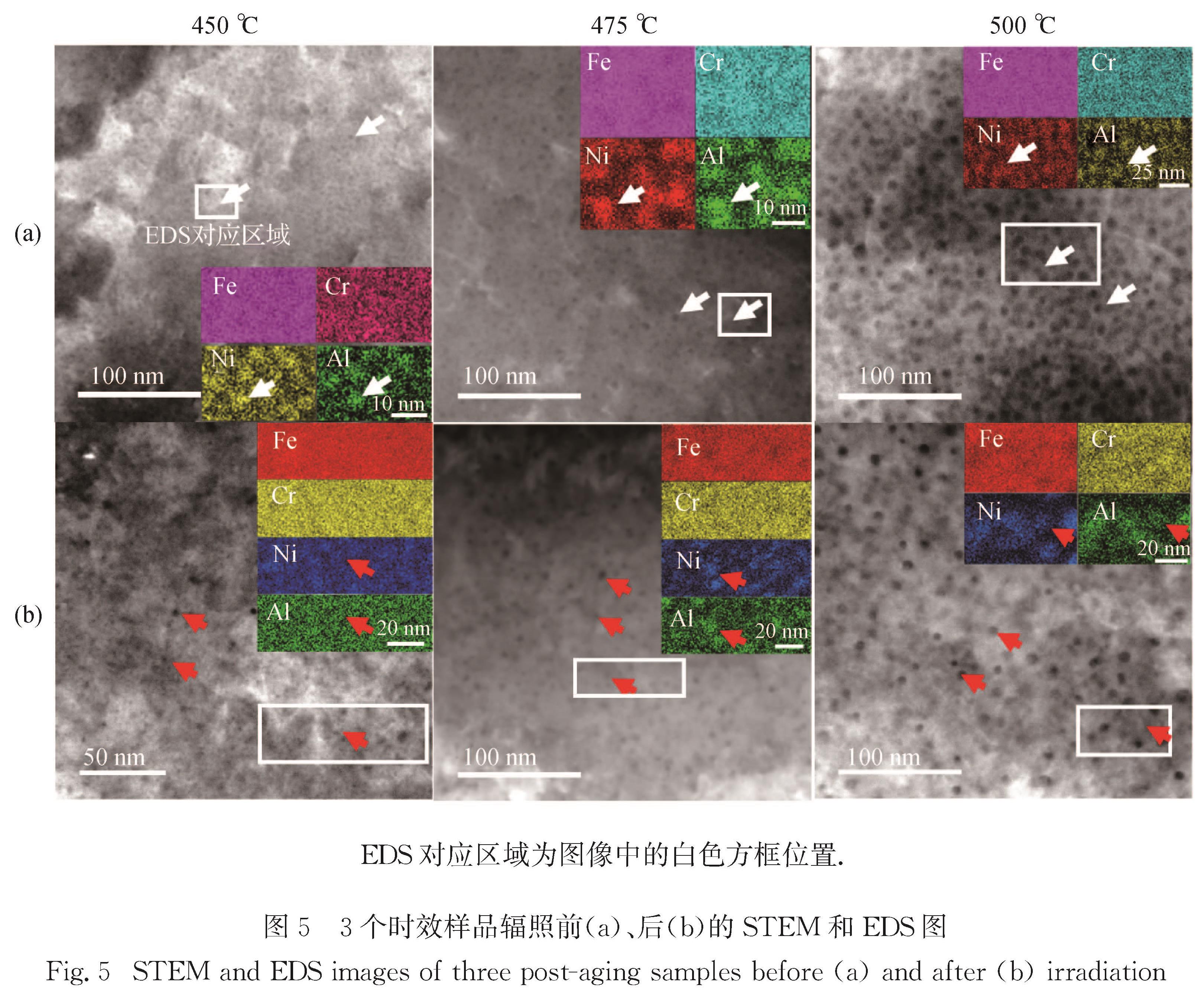

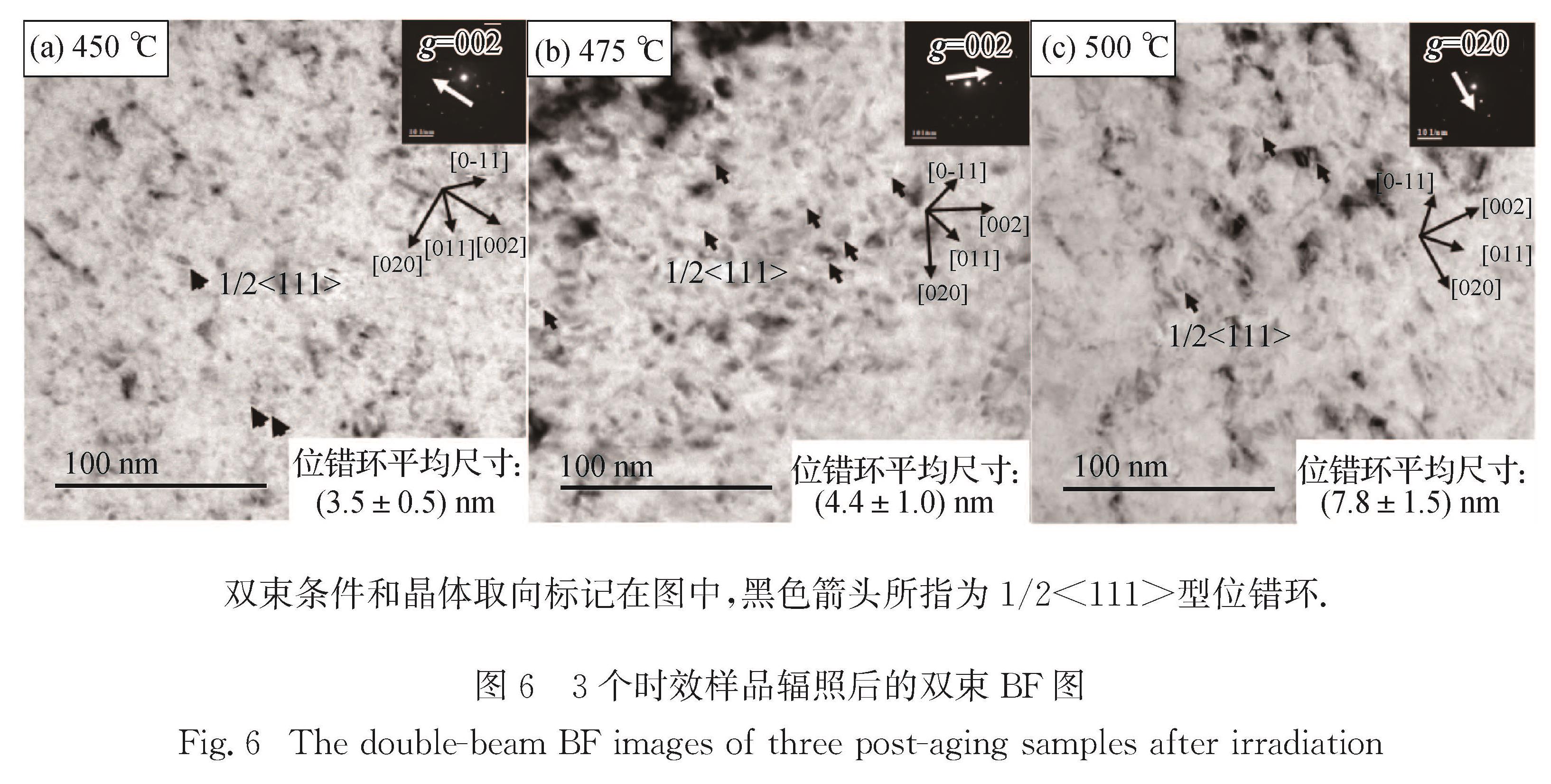

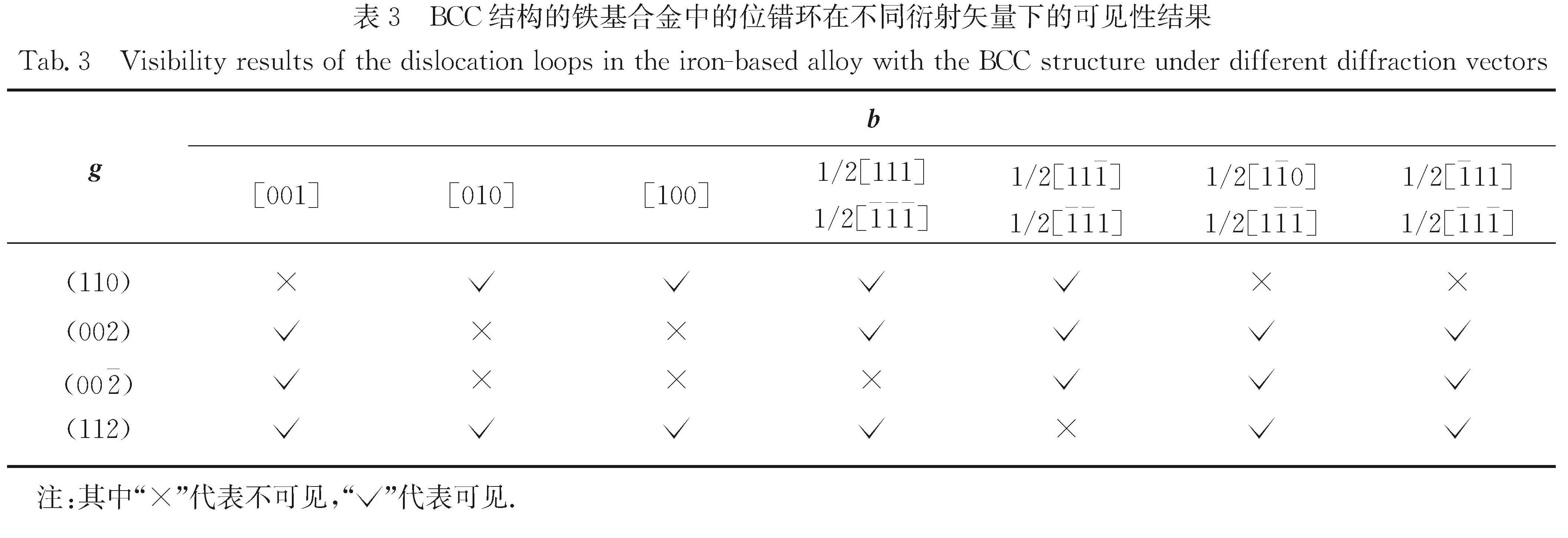

Results: Regular TEM observation was conducted on the aging samples. The size of B2 NiAl precipitates was found to be 2.5, 4.9 and 8.1 nm in samples aged at 450, 475 and 500 ℃, respectively. A series of irradiation experiments with 400 keV Fe+ ions were carried out, and the equivalent accumulated damage of the total flux was calculated with SRIM software as 8 dpa. Afterwards, the selected area electron diffraction (SAED) pattern (<001>//g=<000> ) related with the precipitates in 450 and 475 ℃ aging samples were disappeared. In the 500 ℃ sample, such pattern was weakened. STEM and EDS results revealed that precipitates densities in matrix decreased by 83%, 71% and 60% of samples aged at 450, 475 and 500 ℃, respectively. Irradiation induced dislocations were observed with a selected TEM dual-beam mode <001>//g=<002>. It is found that dislocations were mostly interstitial-type rather than vacancy-type, most of which were with burger’s vector of a/2<111>. The average sizes of dislocations were (3.5±0.5) nm, (4.4±1.0) nm and (7.8±1.5) nm, respectively.

Conclusion: B2-NiAl precipitates with increased size and reduced densities were observed in samples with higher temperature after 20 h of aging. After the irradiation, the super lattice SAED patterns were lost in samples aged at 450 and 475 ℃ and were weakened in samples aged at 500 ℃. This observation indicated that smaller NiAl precipitates lost its ordered structure as a result of irradiation damage and dissoluted in matrix, whereas some larger precipitates in 500 ℃ survived, as demonstrated by the SAED, STEM and EDS results. The size of irradiation induced dislocation loops in the sample aged at 450 ℃ was the smallest, indicating that 450 ℃ was a favorable aging temperature for PH 13-8 Mo to achieve better irradiation resistant properties in nuclear applications.

第二相颗粒会随着辐照损伤的累积而被破坏,研究不同尺寸第二相颗粒在辐照下的演化差异对于核用第二相增强合金的开发设计具有重要意义.以PH 13-8 Mo马氏体时效钢为研究对象,在室温下进行400 keV Fe+辐照损伤试验,针对合金中第二相颗粒辐照稳定性特征和辐照诱导缺陷进行分析.采用不同时效条件,分别制备了包含平均尺寸为2.5,4.9和8.1 nm的金属间化合物NiAl的合金样品.通过透射电镜观察分析发现,累积辐照损伤达8 dpa后,除8.1 nm的NiAl相样品中有微弱的超点阵结构外,其他尺寸样品的析出相均由于辐照损伤破坏了超点阵结构; 析出相NiAl尺寸为2.5 nm的样品中产生的辐照诱发间隙型位错环尺寸最小,为(3.5±0.5)nm.