< br/>通信作者:394504676@qq.com < br/>

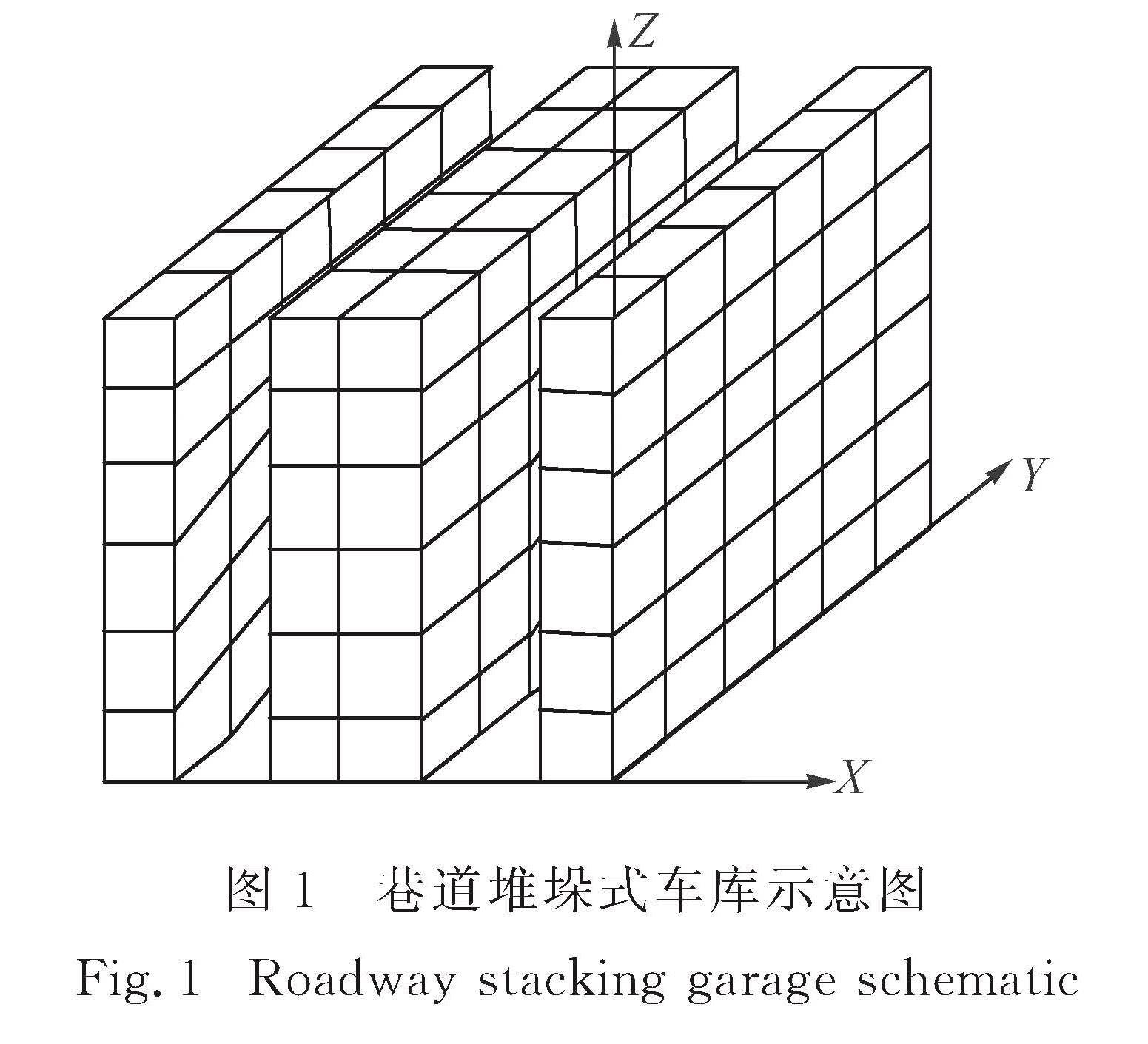

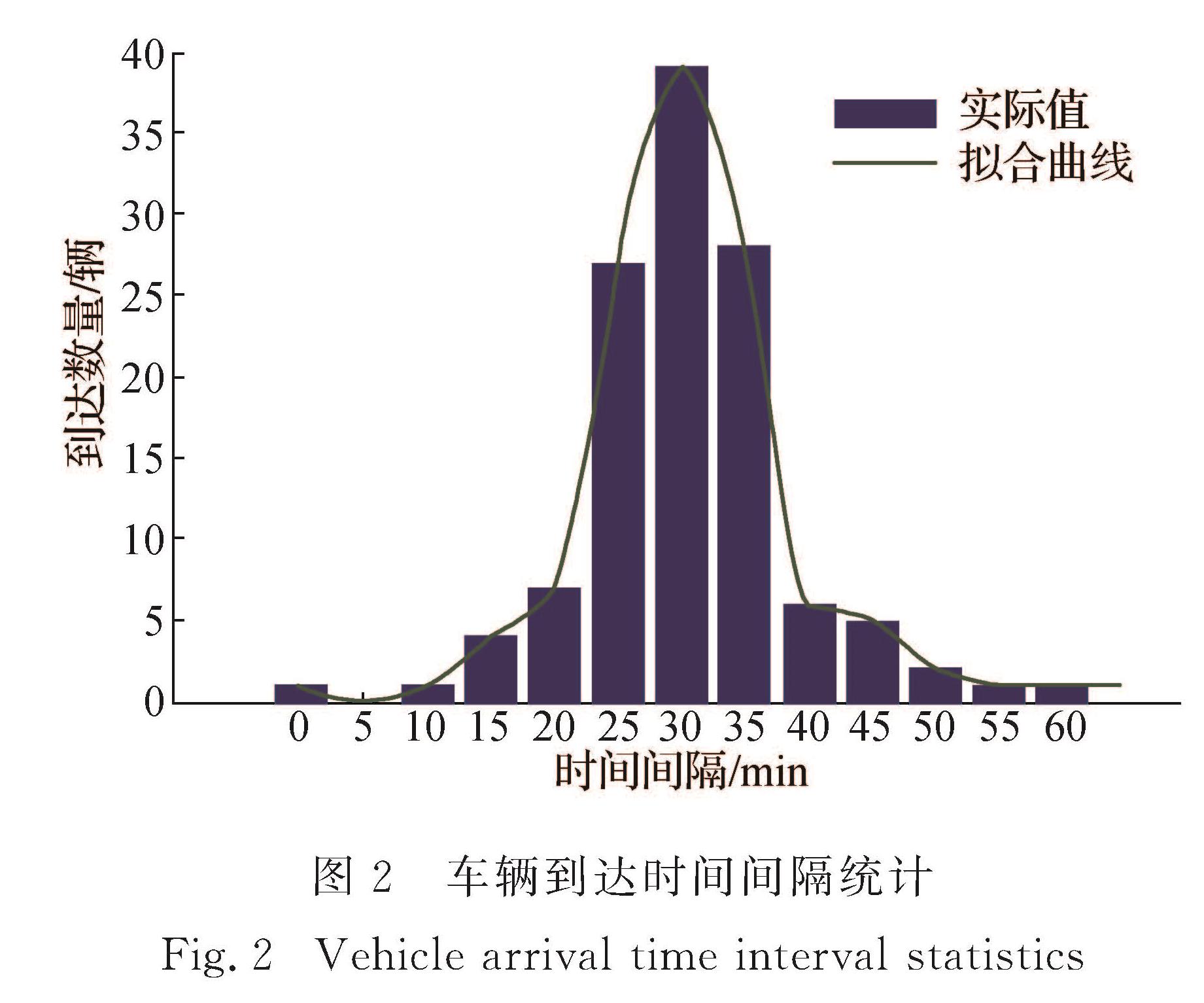

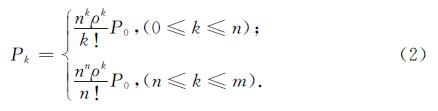

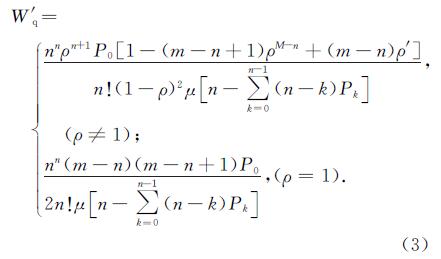

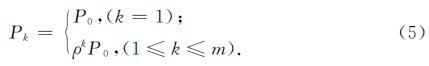

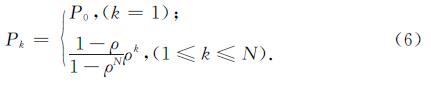

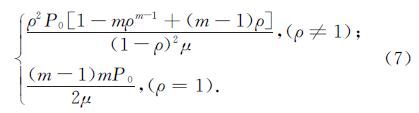

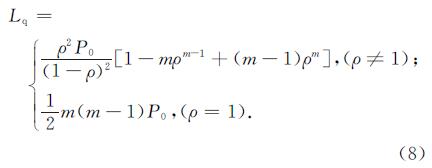

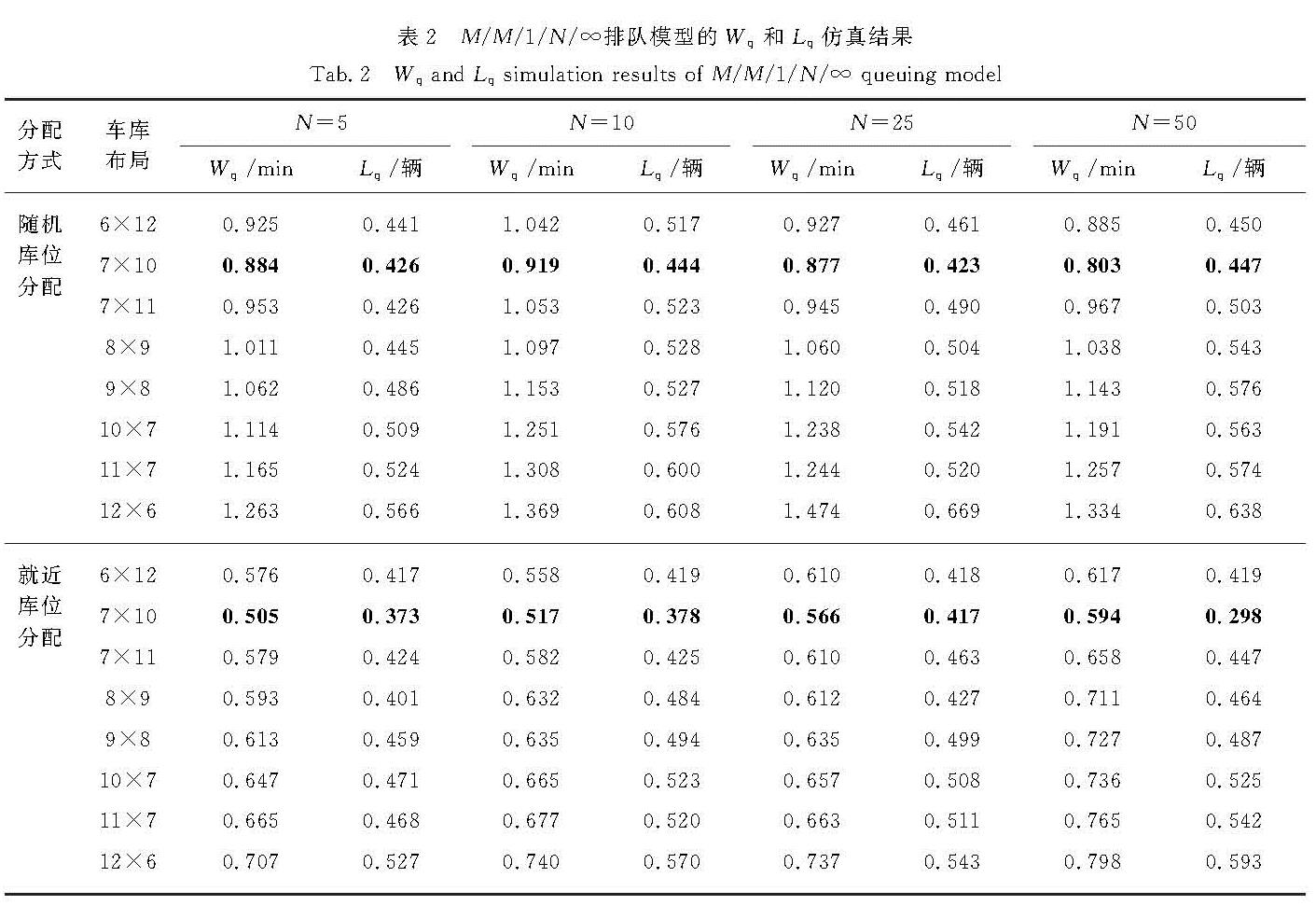

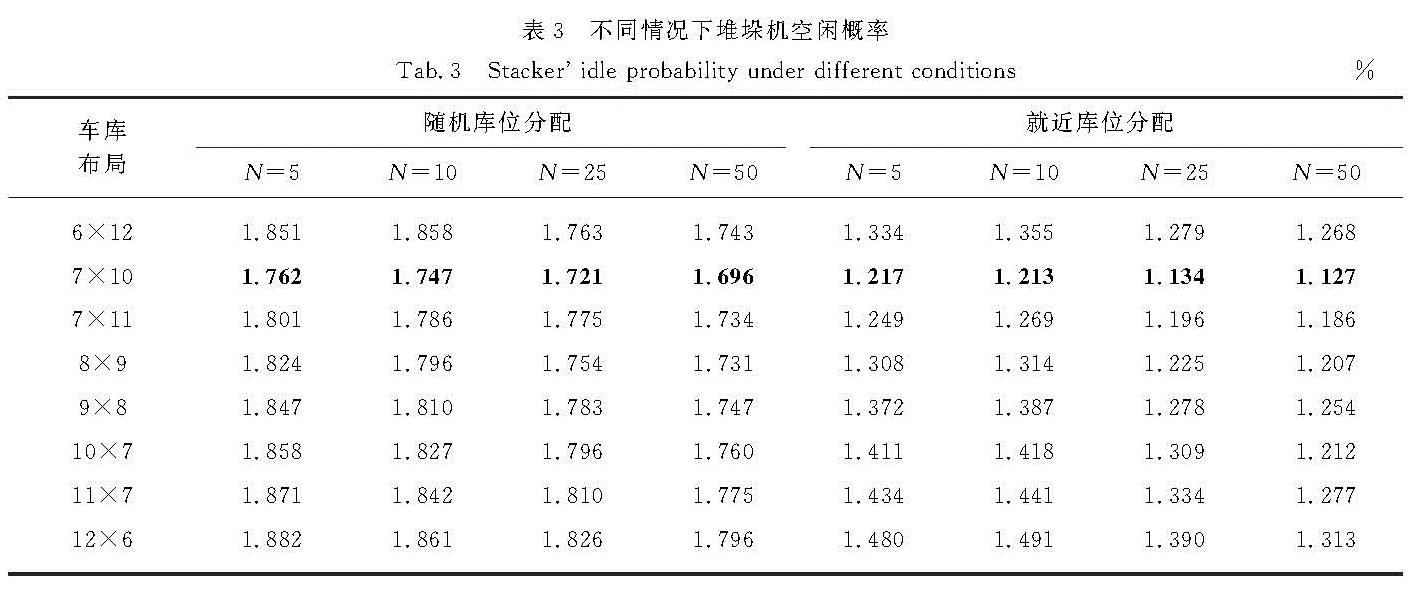

为了提高立体车库的服务效率,以排队论研究了巷道堆垛式自动化立体车库.在顾客的平均等待时间和平均等待队长的参考标准下,分析了单服务台系统的车库在随机分配和就近分配两种库位分配情况下的布局方案.结果表明:1)M/M/1排队模型时,4层6列的库位布局的效果最佳,而且就近库位分配策略下顾客平均等待时间和平均等待队长比随机库位分配策略分别减少了约0.33min和0.07辆;2)M/M/1/N/∞排队模型时,排队系统容量分别为5,10,25,50辆时,7层10列的库位布局的效果最佳,而且就近库位分配策略下顾客平均等待时间、平均等待队长和堆垛机空闲概率比随机库位分配策略分别缩短了约0.2~0.4min、0.006~0.149辆和0.534~0.587个百分点.

To improve the service efficiency of the stereo garage,the roadway stacking automatic stereo garage,we have studied by queuing theory.Take the customer's average waiting time and the average waiting captain's as the standard,the garage layout with single service desk system is analyzed under the strategy of random and nearest allocation.Results show that:1)When the queueing model is M/M/1,the 4-storey and 6-column storage location layout has achieved the best result,and the nearest allocation is better than the random allocation strategy.For the nearest allocation strategy,the average waiting time of customersand the average queue length is reduced by about 0.33 minutes and 0.07(by car number)separately.2)When the queueing model is M/M/1/N/∞ and the queuing system capacity is 5,10,25,and 50(by car number)respectively,the 7-storey and 10-column storage location layout has achieved the best result.And compare with the random allocation,the average customer waiting time,the average queue length and stacker idle probability of nearest allocation is reduced by about 0.2-0.4 minutes,0.06-0.149(by car number)and 0.534-0.587 percent separately.