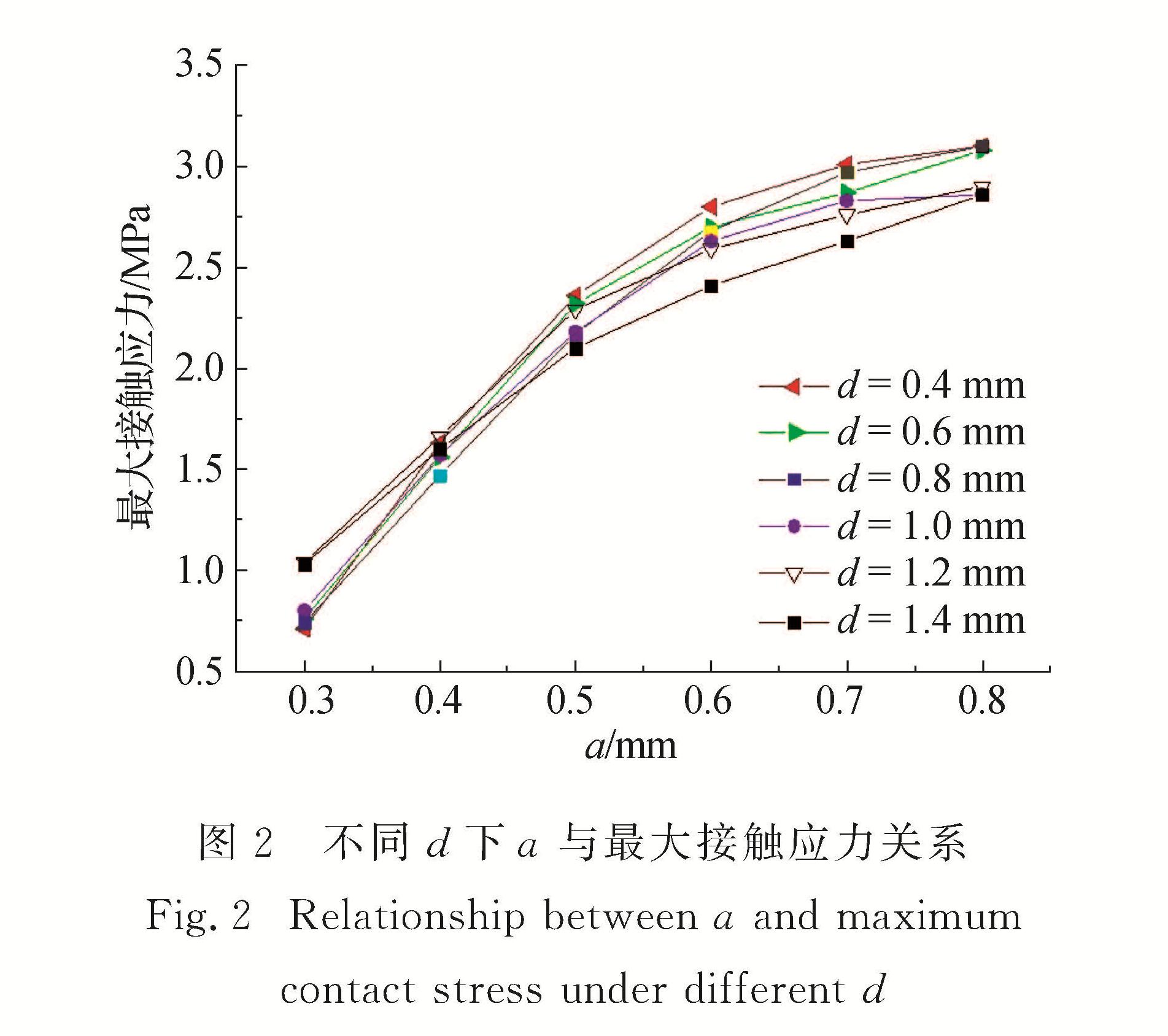

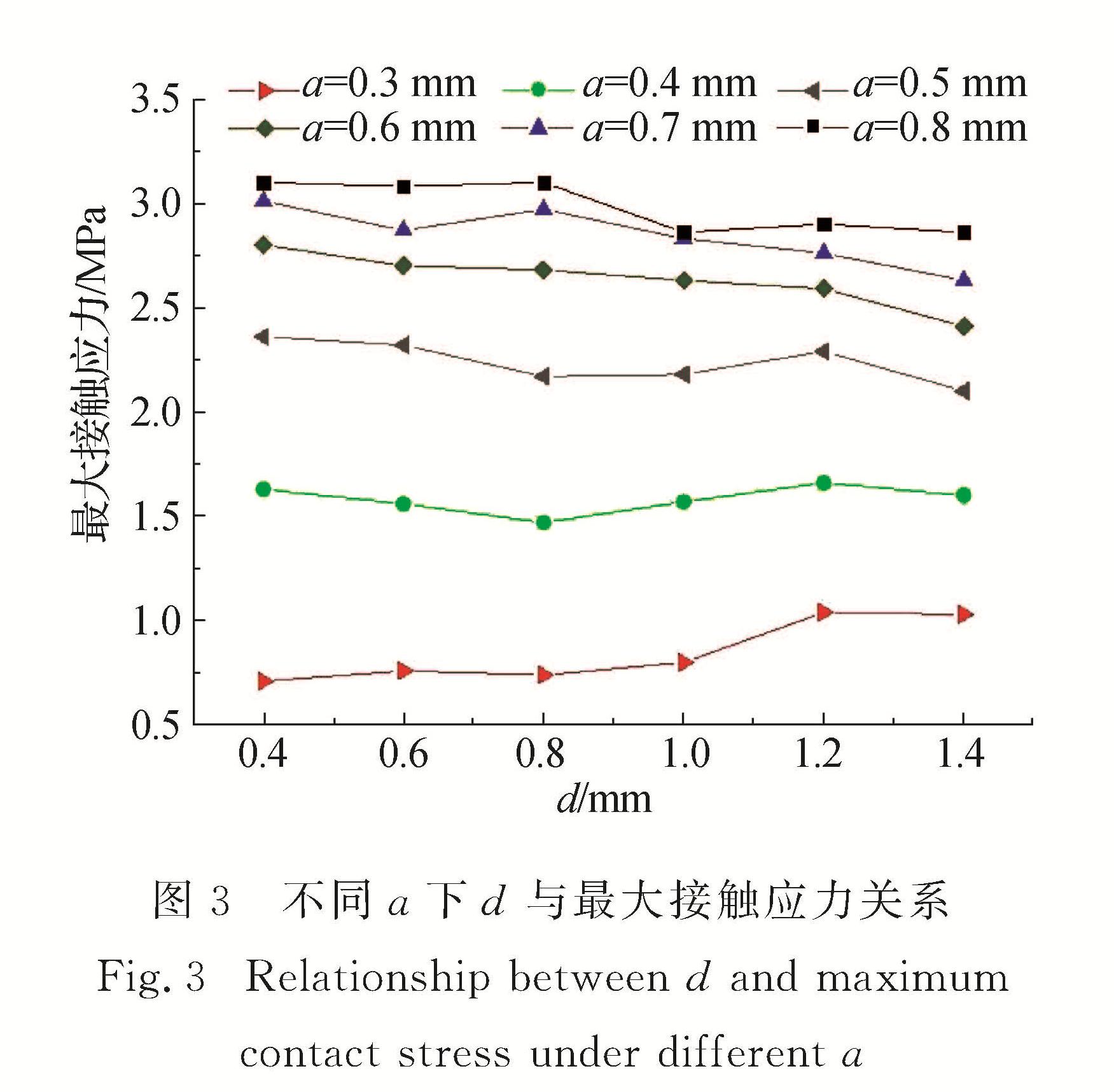

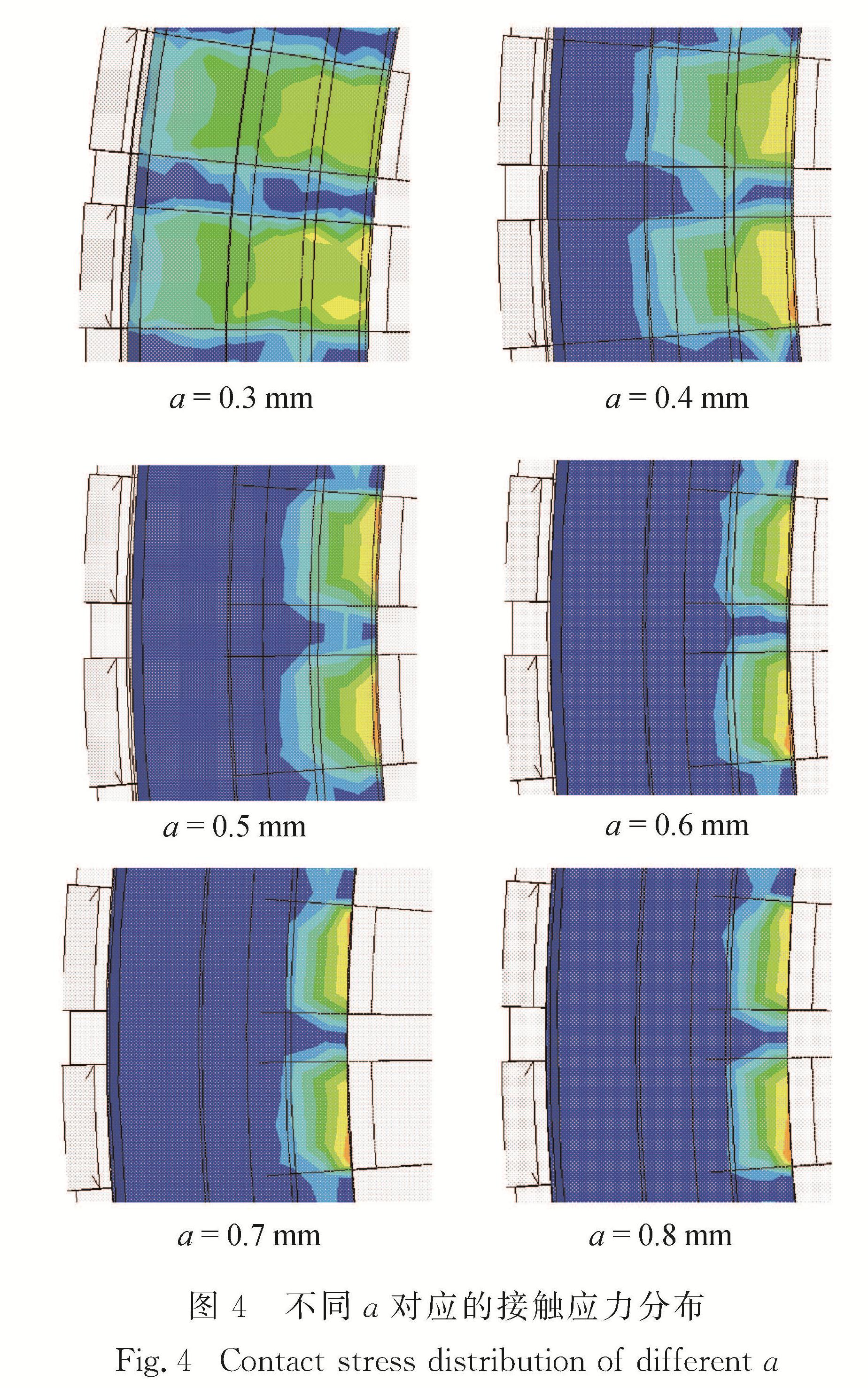

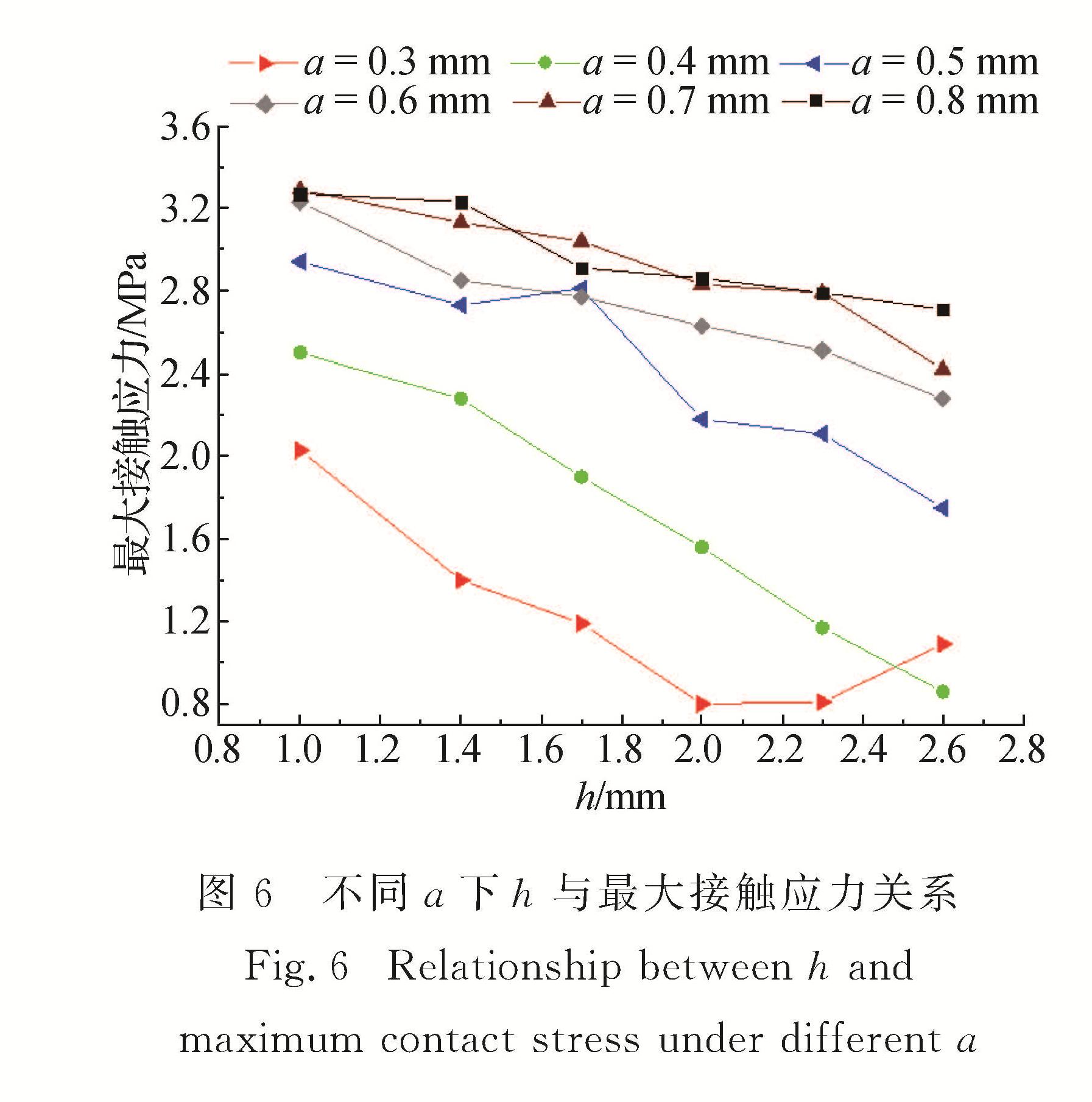

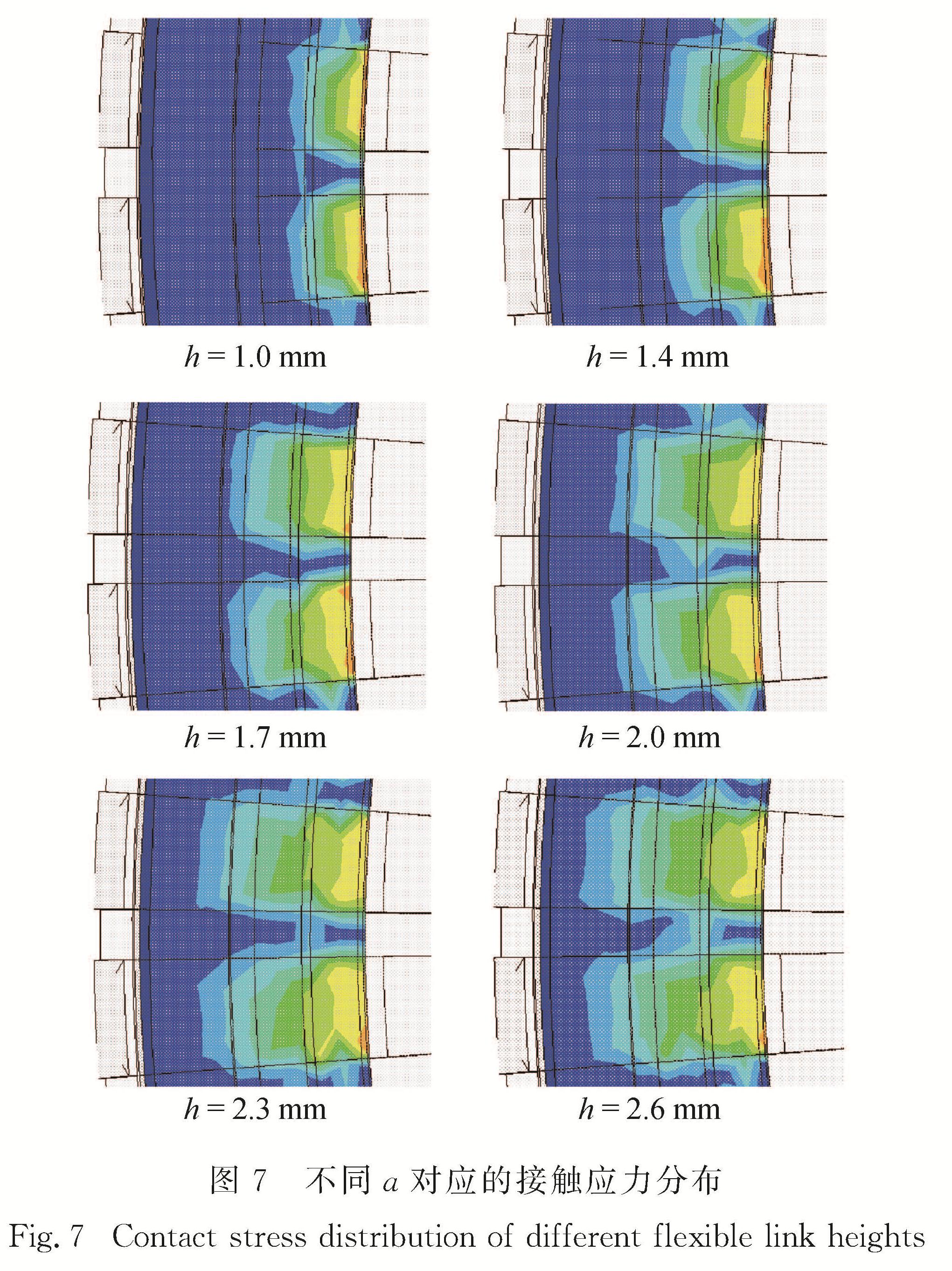

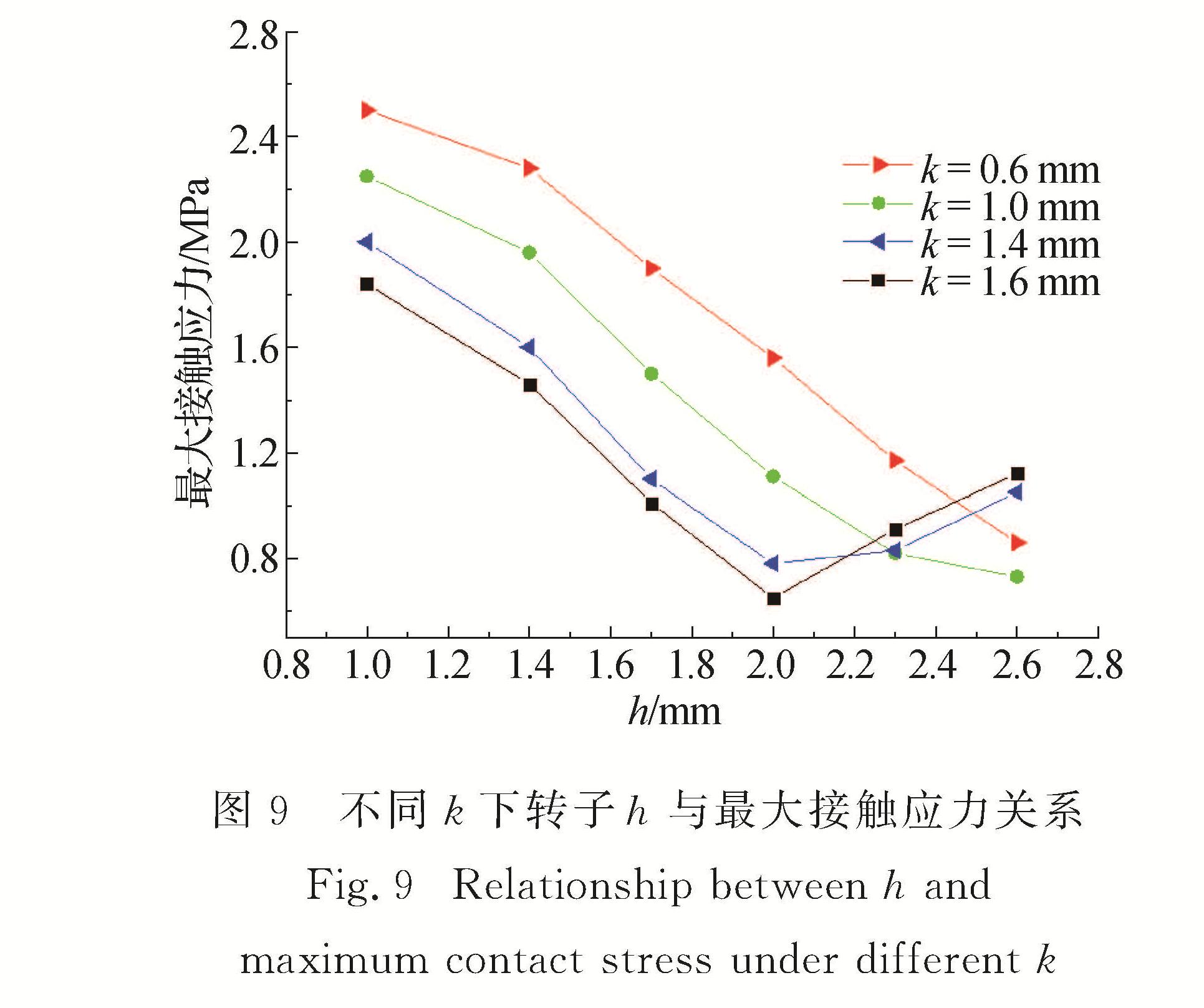

为了提高行波旋转型超声电机的机械性能,根据超声电机柔性部分的特点,构建影响电机机械性能的4个主要参数(转子腹板厚度、定子腹板厚度、柔性部分宽度和高度).基于ANSYS软件仿真分析在相同边界条件下各影响参数对电机接触面接触应力分布的影响,优化结构参数使定子和转子接触应力均匀分布.仿真分析结果表明:在施加相同预压力条件下,定子和转子腹板厚度对于接触应力分布的影响最小,而柔性部分的宽度和厚度影响最大,最优结构参数设计为转子腹板厚度为1.0 mm,柔性部分高度为2.0 mm,柔性部分宽度为0.4 mm,定子腹板厚度为1.6 mm.

To improve the mechanical performance of the traveling wave rotating ultrasonic motor according to the structural characteristics of the ultrasonic motor's flexible part,we have established four main parameters(the thickness of rotor web,the thickness of stator web,the width and height of flerible part)affecting the mechanical performance of the motor.The motor analysis model is based on ANSYS software.Under the same boundary conditions,the influence of all parameters on the contact stress distribution of the motor contact surface is optimized,such that the contact stress of the stator and rotor evenly distributed.The analysis shows that under the same pre-stress conditions,the thicknesses of the stator and rotor web exert the least influence on the contact stress distribution,while the width and thickness of the flexible part do the most.Finally,optimal structural design parameters are found to be the rotor web thickness of 1.0 mm,the flexible part height of 2.0 mm,and the flexible part width of 0.4 mm and the stator web thickness of 1.6 mm.