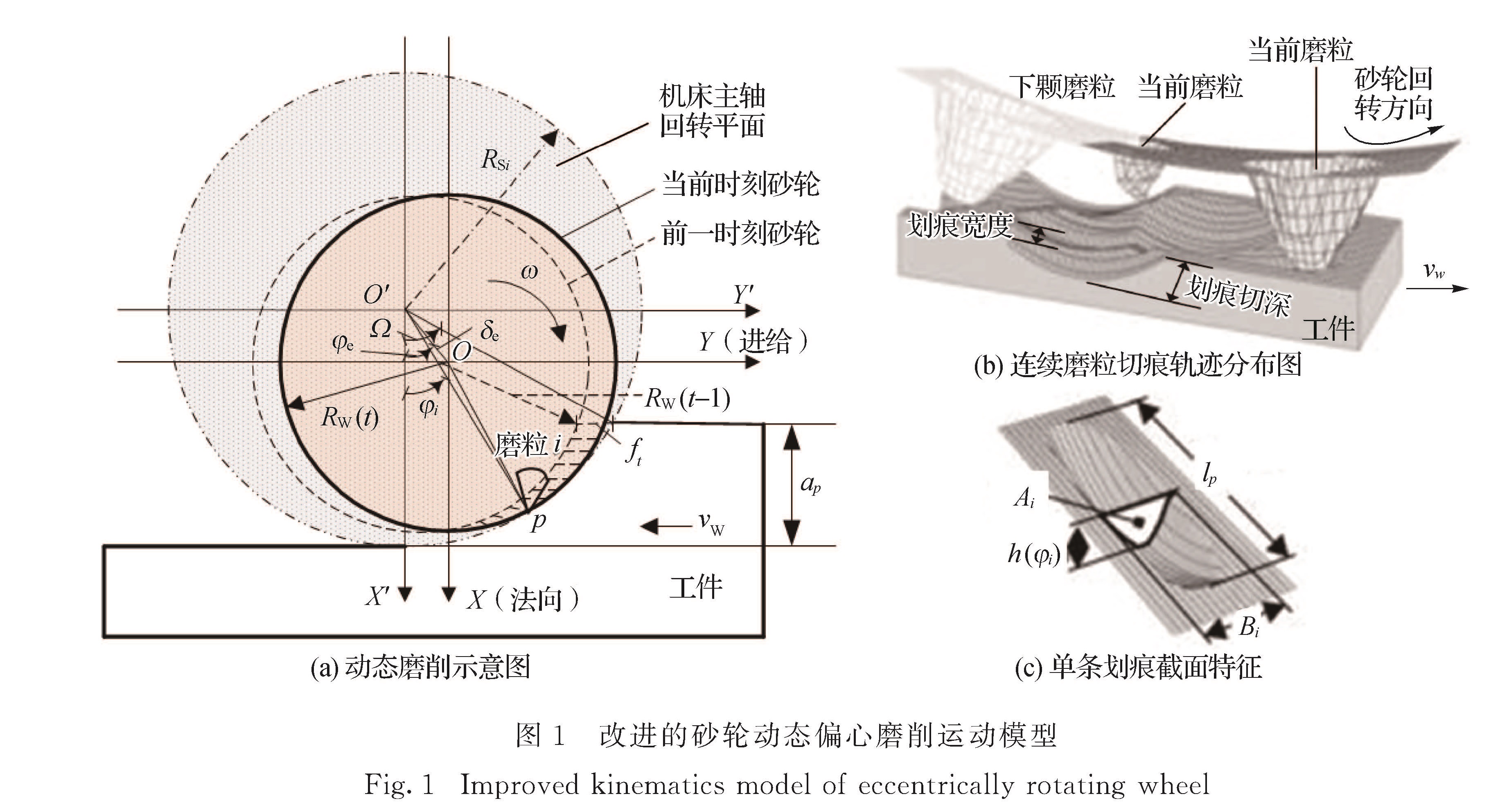

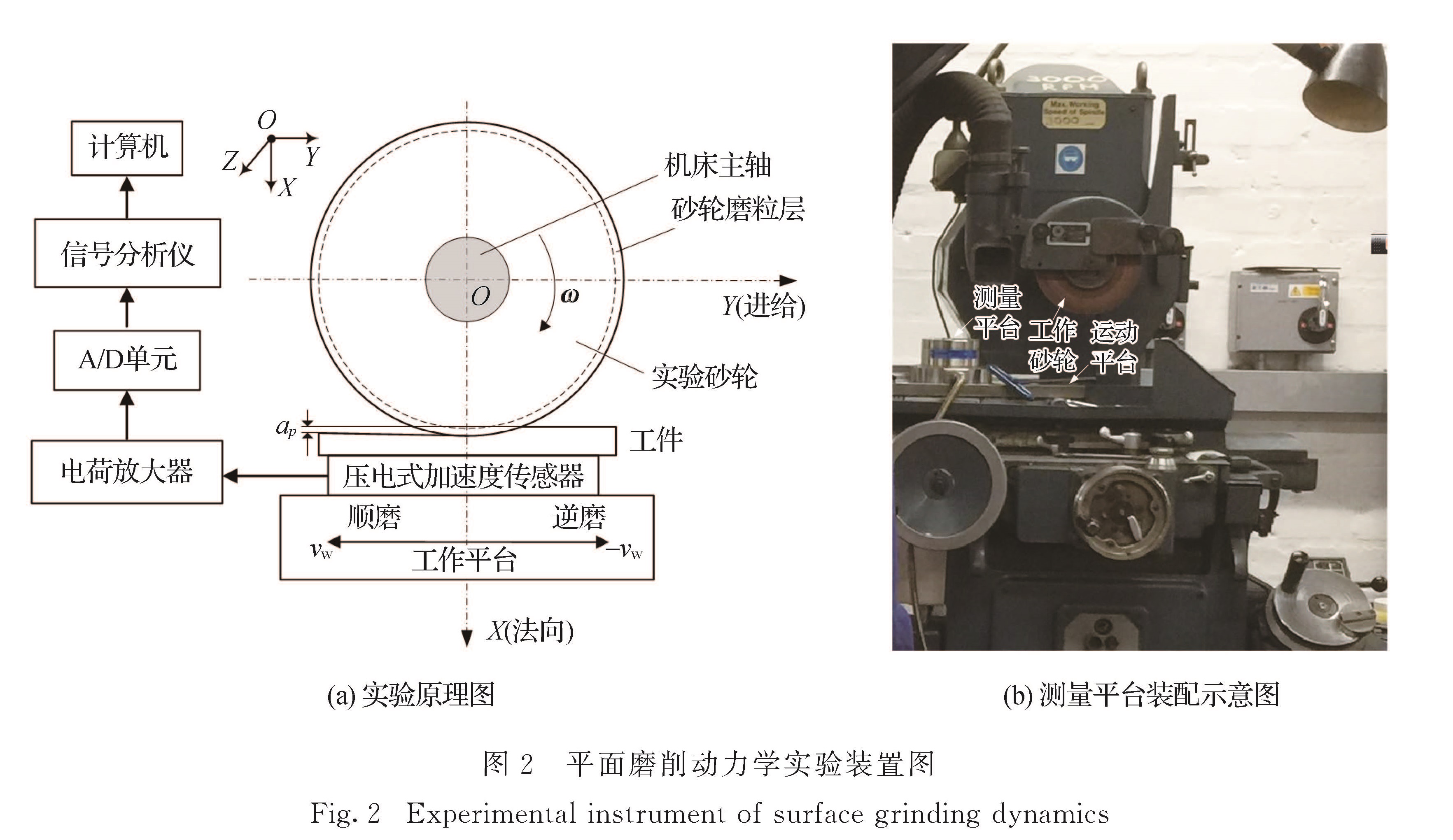

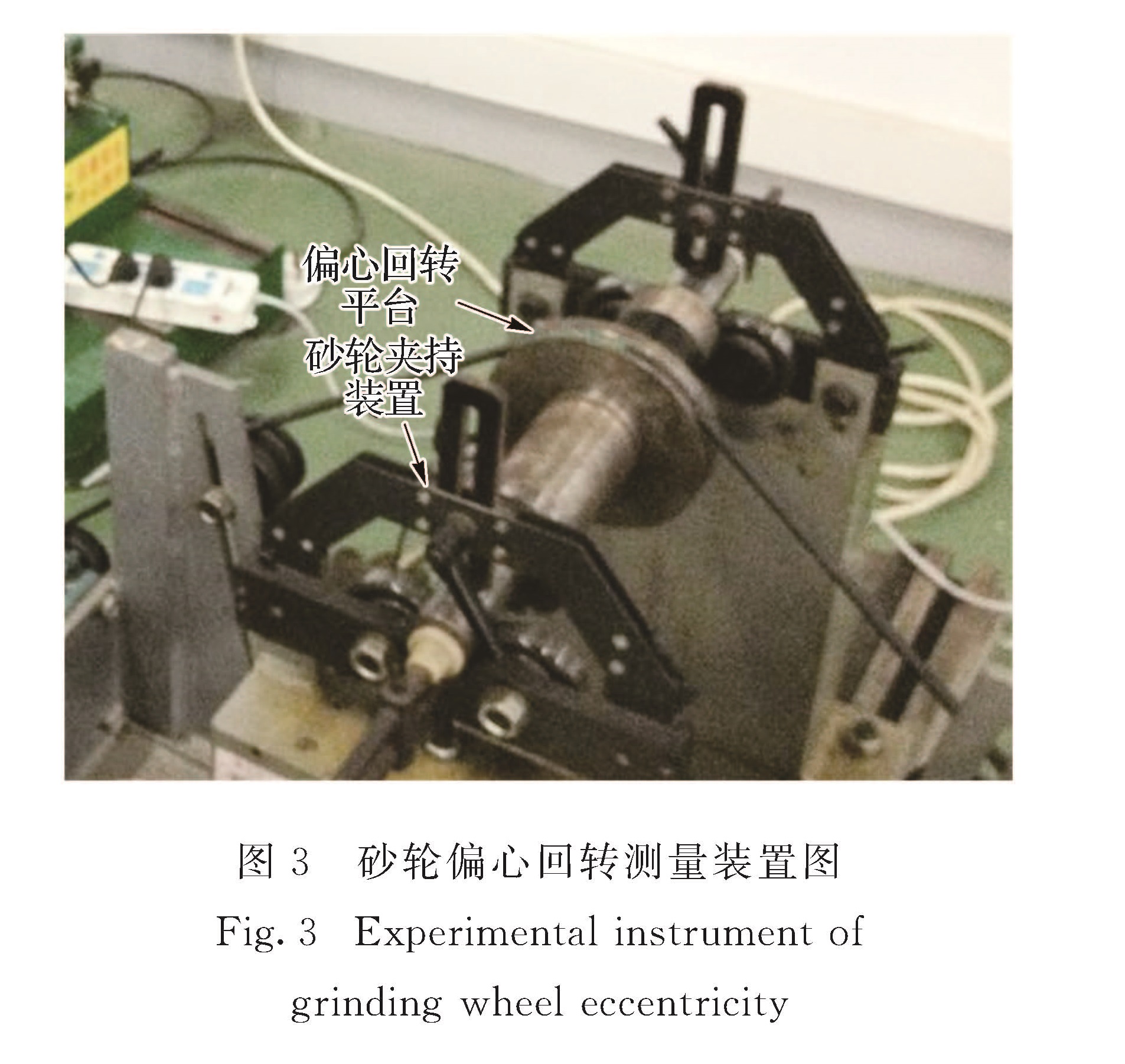

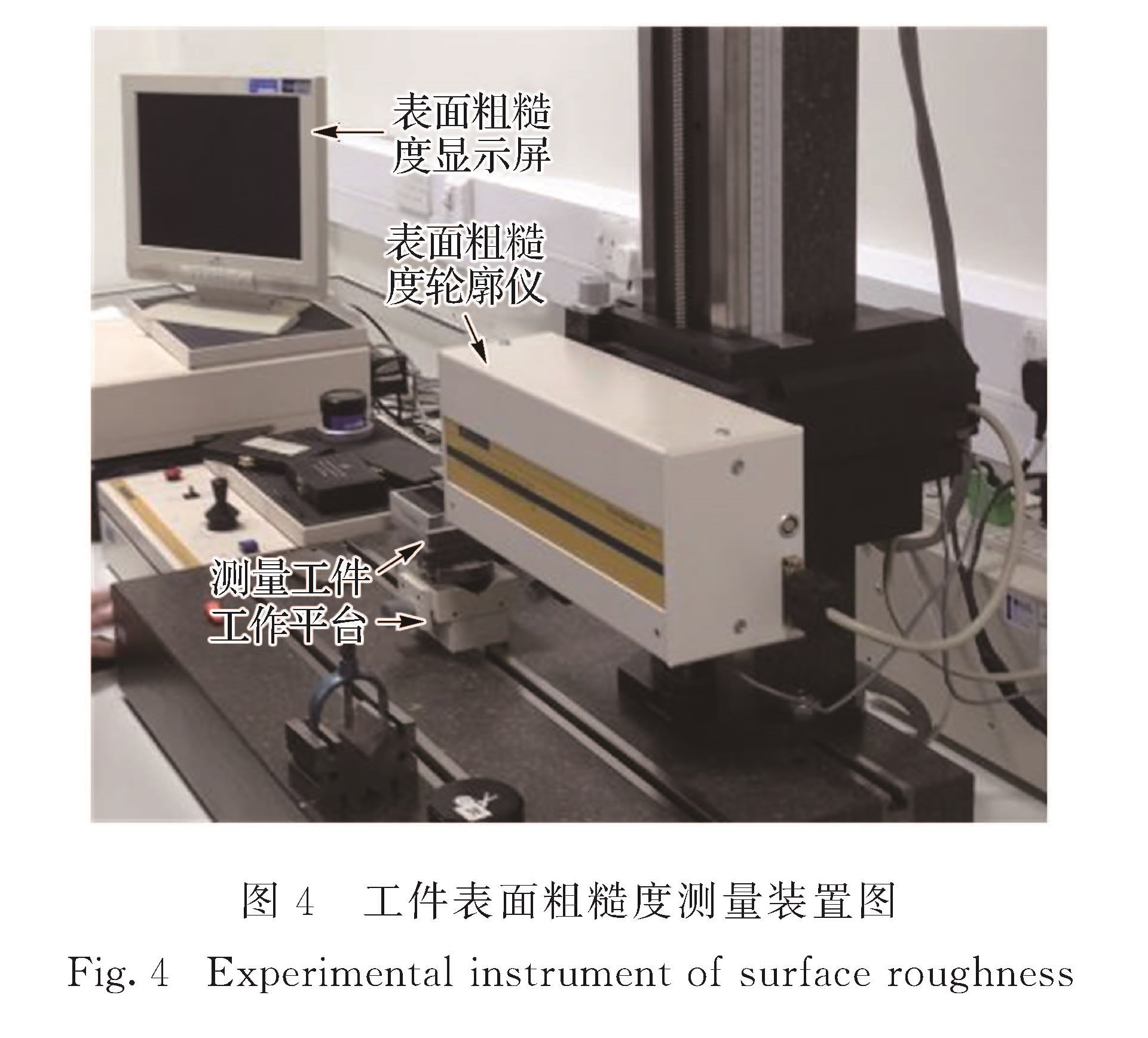

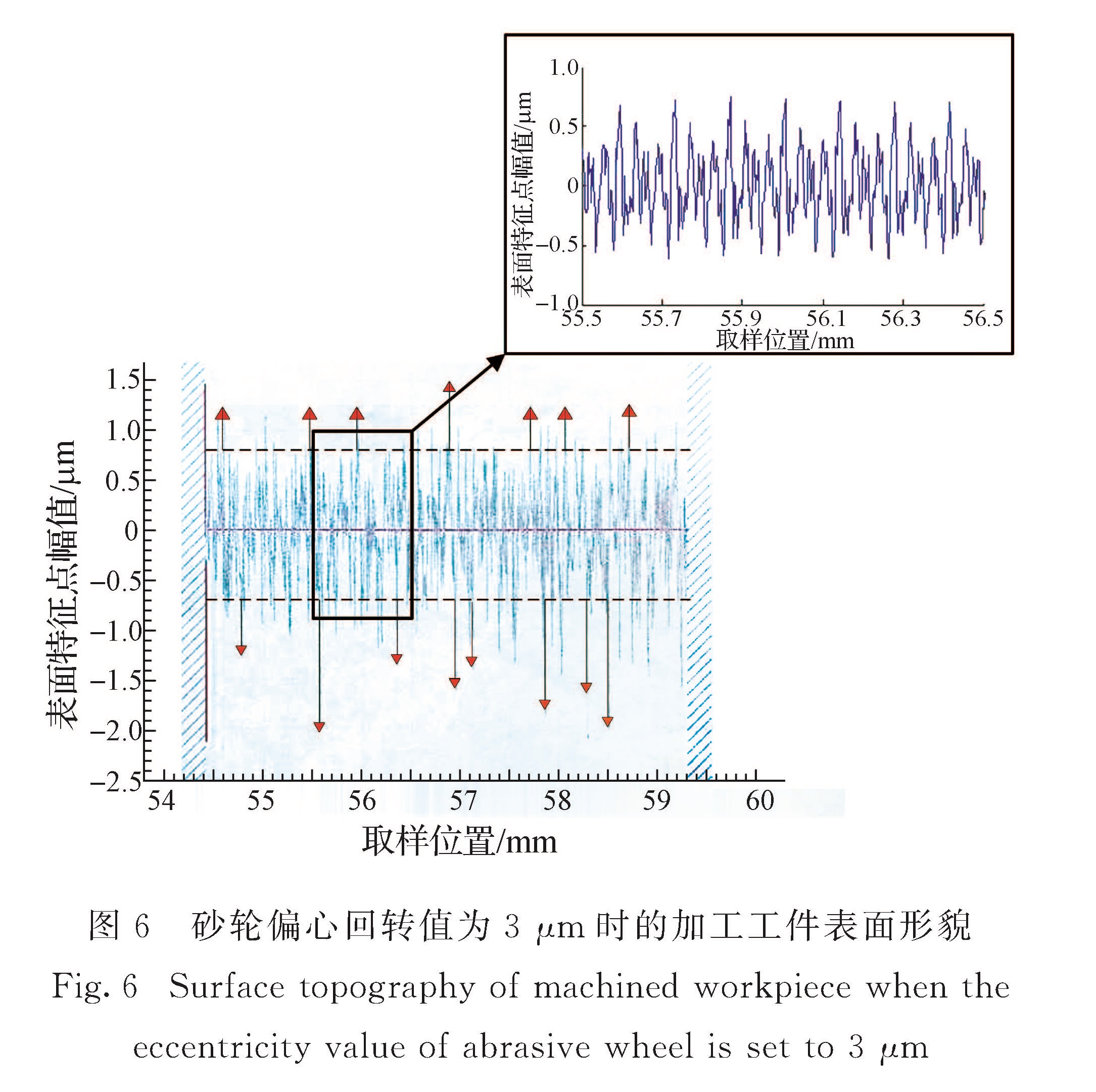

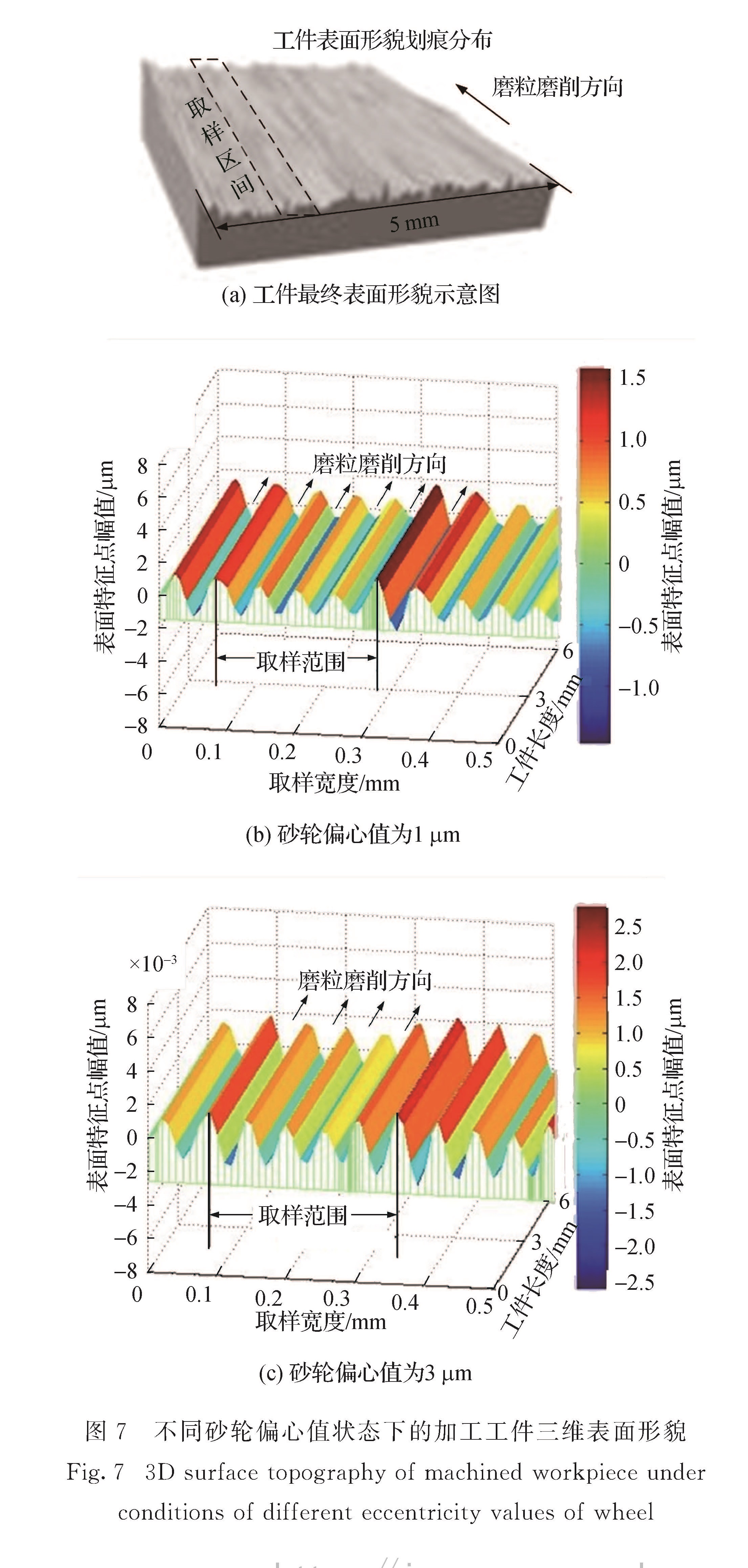

因主轴装配精度和动态磨耗等导致的砂轮偏心回转行为对精磨表面质量具有重要影响.以砂轮偏心顺磨为例,改进相邻磨粒瞬态切削深度(简称切深)模型并深入分析偏心激振机理.加工表面划痕截面特征测量结果与三维表面形貌仿真结果的比较表明:砂轮偏心回转微量变化对同等实验条件下的工件表面形貌和加工精度具有较大影响.当砂轮偏心值在1 μm以内时,相邻磨粒连续切深分布均匀,加工表面划痕平均切深Rt约为预设切深值ap的40%,表面粗糙度的实验测量与仿真结果基本一致; 当其值达到3 μm时,工作磨粒切入-切出瞬态冲击与强迫激振加剧,使得加工表面最大划痕深度超过ap值的5.6%左右,工件表面粗糙度与稳定状态相比增加近1倍,加工表面划痕深度非线性分布呈现复杂特征.

Kinematic/dynamic behaviors of abrasive wheels under eccentrically rotating conditions,which result from low wheel-spindle assembly accuracy of the machining tool and non-uniform wear distribution of the wheel,inevitably influence the final surface precision of machined product.In the paper,the governing mechanism of eccentrically rotating behaviors of the wheel on instantaneous depth of cut and chatter characteristics between adjacent abrasive grits in contact zone is investigated,then the improved analytical model of depth of cut in down-grinding is presented.By comparing 3D simulation results with experimental signals on micro-morphology of workpiece surface,the result demonstrates that the influence of eccentrical rotation deviation of abrasive wheels on surface topography and machine precision is great under consistent experimental conditions.The tendency of cutting depth distribution of adjacent abrasive grits remains stable and the average depth of scratching marks on sampled workpiece surface is almost 40% of preset cutting depth prior to grinding when the eccentricity value of the wheel is controlled within 1 μm.Nevertheless,due to comprehensive influence of dynamic impact in grits cutting-in phase and forced-exciting vibrations of abrasive wheel when the eccentricity value of the wheel is up to 3 μm,the depth of scratching marks is bigger by around 6% than the predetermined value in machining process,leading to approximately double reduction of surface roughness comparing with the result of stable machining situation.Moreover,complex and nonlinear depth distributions of scratching marks on machined surface exists.