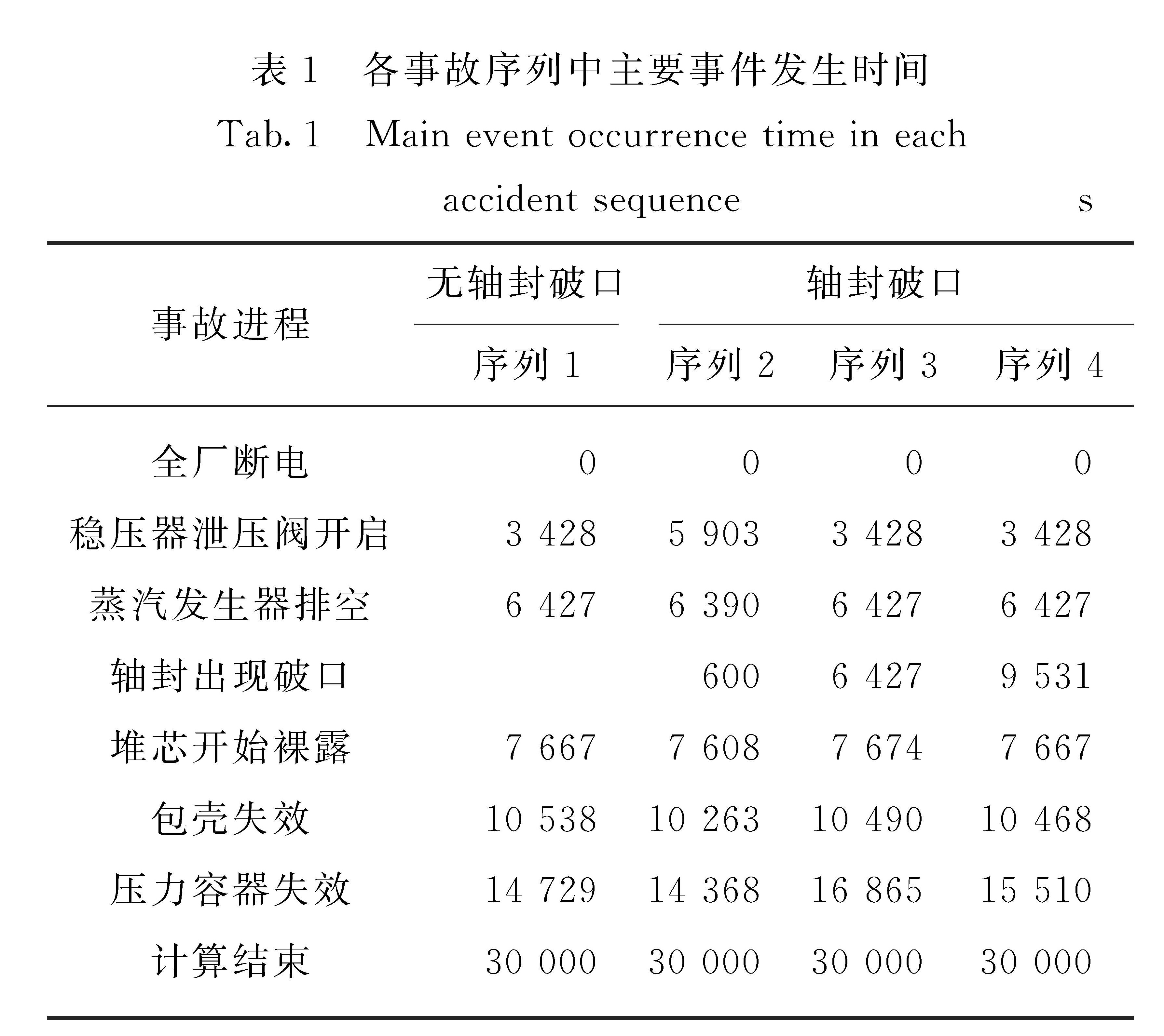

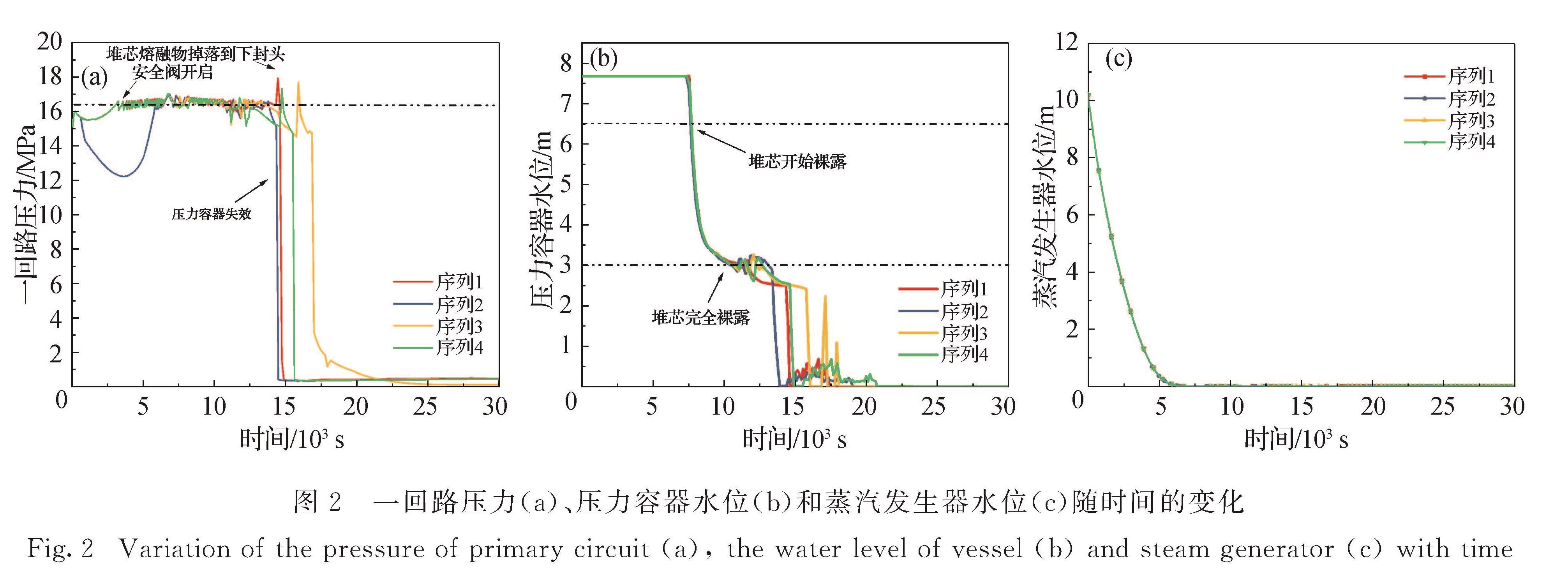

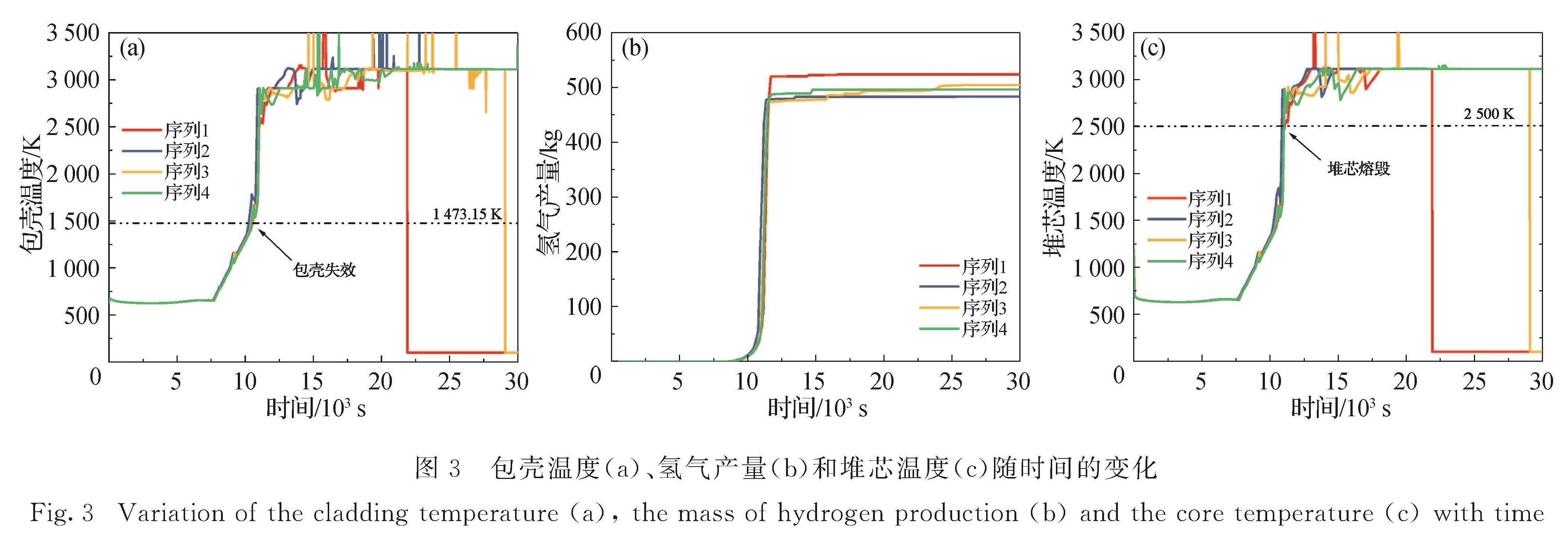

全厂断电事故是导致核电厂发生严重后果的重要事件之一.采用模块化事故分析程序对CPR1000全厂断电事故进行建模与分析,计算一回路压力、压力容器水位、堆芯温度等参数,详细分析了事故进程.分析结果显示:全厂断电事故会导致反应堆压力容器在高压下失效,这将会有安全壳直接加热的风险; 同时,事故过程中会产生大量氢气,这部分氢气会逐步迁移到安全壳或者辅助厂房中,从而带来氢气爆炸的风险.针对全厂断电时主泵容易出现轴封破口这一问题,选取了早、中、晚3个时期的事故序列,对轴封破口发生时间做敏感性分析.结果表明,早期破口会加速严重事故的进程,而较晚时间发生破口,尤其是事故中期发生破口能较好地延缓压力容器损毁进程.相关数据可为有关人员防范和缓解严重事故提供参考.

Station blackout(SBO)is one of the important events in nuclear power plant(NNP)that can lead to serious consequence.We adopt the modular accident analysis program of CPR1000 to model and analyze the SBO accident.We analyzed the accident process of SBO accident for CPR1000 in detail by calculating parameters such as main circuit pressure,vessel water level,core tem-perature, and so on.The results show that SBO accident leads to vessel failure under high pressure,which causes the risk of containment direct heating.At the same time,large amounts of hydrogen is produced in the SBO accident.This part of hydrogen gradually migrates to the containment or auxiliary room,resulting in the risk of hydrogen explosion.As for the problem that the main pump is easy to break in SBO accident,we selected three periods of the accident sequence,the early period,middle period,and late period,to do the sensitivity analysis of time.The results show that seal loss-of-coolant accident(LOCA)in the early period accelerates the process of vessel failure,and in the later period and especially in the middle period,seal LOCA can delay the accident process.Data in this paper will provide a reference for relevant personnel for preventing and mitigating of serious accidents.